Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:03

At the core of engineering

0:05

and manufacturing is the transformation

0:07

of materials. A tree becomes

0:10

a book, a stone is

0:12

transformed into a concrete bridge,

0:14

rocks into steel and glass

0:17

skyscrapers. Each of these

0:19

transformations are inefficient. Raw materials

0:21

are lost to waste, mechanical

0:23

energy is converted into lost

0:26

heat. In this inefficiency, we

0:28

gradually chip away at our

0:30

planet and its livability.

0:32

If we are to maintain

0:35

our planet, we must

0:37

find new, more efficient

0:39

ways to perform these

0:41

transformations. We must move

0:44

from a linear economy

0:46

where materials are

0:49

extracted, transformed, used

0:52

and then thrown away.

0:54

Instead, we must focus

0:56

on reusing and build

0:59

a truly circular

1:02

economy. profiling shortlisted

1:04

entries in the

1:07

Engineering Matters Awards,

1:09

we are looking

1:12

at how engineers

1:14

are helping to

1:17

transform the world,

1:19

by making manufacturing

1:23

and transport

1:25

efficient and

1:28

sustainable. What we've

1:30

done, we've developed a bio

1:32

adhesive to replace the current

1:35

glue used in engineered wood

1:37

panels. That glue is toxic

1:39

and is carcinogenic and has

1:41

a massive CO2 footprint. Victoria

1:43

Garcia is CEO of bind ethics.

1:46

Every time when I talk about

1:48

the bio, this doesn't sound like

1:50

a sexy topic, but truth is

1:52

that it's a problem that everybody

1:54

uses every day. Like, unless you

1:56

don't have IKEA furniture, which would

1:58

be really rare. So then for

2:00

example, what is it used? It's

2:03

like wood panels, so ingenuity panels,

2:05

and that is plywood, particle board,

2:07

MDF. And we use them, for

2:09

example, the typical IKEA board would

2:12

be particle board, but they're

2:14

very commonly used in construction,

2:16

the construction industry. The current

2:18

formaldehyde-based glue used in all

2:20

kinds of wood products is

2:23

very toxic. So then basically the

2:25

final piece of furniture, it's not

2:27

sustainable at all, which is a pity

2:29

because 90% of the product is wood,

2:31

but that's why, you know, it

2:34

is wood and then you're like,

2:36

when you're done with your IKEA

2:38

furniture, you know that you have

2:40

to bring it to the skip,

2:42

you can not, let's say, burn

2:44

it in your chimney for energy

2:46

in winter. You can do it

2:48

with pallets, and people do it

2:50

with pallets, but you can't do

2:52

it with furniture, but you can't

2:55

do it for a bioadhesive made

2:57

from industrial food waste.

3:01

So then, as I say, like,

3:03

the current glue comes from

3:05

fossil fuels, obviously, and our

3:07

glue comes from industrial food waste.

3:09

So we take food waste, and

3:11

I purify in the lab, do

3:13

my chemical magic, then we have

3:15

the clue that we combine with

3:18

wood, the material engineers, that's that,

3:20

and then we have the both.

3:22

The key ingredient is brewer's waste.

3:24

Basically, the... the key components that once

3:26

you have brewers waste you have a

3:28

lot of proteins and proteins have been

3:30

actually the glue. It used to be

3:33

the glue of the past. So it's the

3:35

protein content that makes it a good

3:37

adhesive. Bind ethics glue removes fossil

3:39

fuel and other toxic chemicals

3:41

from the process, creating a

3:44

more recyclable end product. So then

3:46

basically you can recycle it because

3:48

the glue acts differently. but also is

3:50

the fact that then you could burn it in the

3:52

chimney for energy that we do with the pilots for

3:55

example or if you want to bring it to the

3:57

landfill you can leave it there and you know that

3:59

over time be degraded the same as

4:01

wood. Like it won't contaminate because

4:03

what happens around the height is

4:06

that it contaminates farther rivers and

4:08

the soil because it's toxic with

4:10

a clue that won't happen. So

4:12

then there are a few of

4:14

the things that most importantly you

4:17

fall within the circular economy

4:19

cycle by taking the waste and

4:21

then give it another life. Not

4:23

placentri also looks at bio-based

4:25

products to solve a waste

4:28

problem. My

4:30

name is States Lee, I'm

4:32

an engineering, my role title

4:35

is the engineering lead at

4:37

Napla, more company that makes

4:39

packaging materials from plants, primarily

4:42

seaweed, to replace single-use packaging

4:44

materials made from plastic. It's

4:47

estimated that 8 million tons

4:49

of plastic makes its way

4:51

into waterways around the world

4:53

every year. So, Nautpla have

4:55

looked to seaweed to

4:58

replace fossil fuel-based plastic

5:00

packaging. The journey started with

5:02

seaweed and the more Rodrigo

5:05

and Pierre, the founders of

5:07

the company, played around and

5:09

other employees underneath them also

5:12

played around with seaweed. The

5:14

more kind of benefits and

5:16

kind of different properties that

5:19

different types of sea weeds

5:21

can have. It's also

5:23

a plant that's very much in abundance. It

5:25

doesn't use fertilizer and doesn't use landmass in

5:27

order to grow. And so it kind of takes a lot

5:30

of boxes in terms of sustainability that we really

5:32

like. We only use like natural materials and

5:34

the bulk of each of our formations for

5:36

each of our different products is primarily seaweed

5:38

seaweed where possible seaweed seaweed where possible seaweed

5:40

seaweed or seaweed seaweed where we seaweed seaweed

5:42

or seaweed seaweed where we seaweed seaweed seaweed

5:44

seaweed or seaweed seaweed seaweed seaweed seaweed seaweed

5:47

seaweed seaweed seaweed seaweed seaweed seaweed seaweed seaweed

5:49

seaweed seaweed seaweed seaweed seaweed seaweed seaweed

5:51

seaweed seaweed seaweed seaweed Nopla have

5:53

made packaging to replace takeaway

5:55

boxes, cutlery and other food

5:58

containers, but they're most unique.

6:00

product aims to replace

6:02

the single use water

6:04

bottle. There's a called

6:07

O. H. O. H. O.

6:09

But it's named that because

6:11

of the experience of actually eating

6:13

one. It makes you go,

6:15

oh, like, oh. But yes,

6:18

that was the inception of

6:20

the company in the first

6:22

product that Roger and Pierre

6:25

made and their goal was

6:27

to really like. see if

6:29

they could offer a different

6:32

solution for packaging liquids, as

6:34

you see, kind of on

6:36

the street, there's bottles everywhere,

6:38

and just seeing if there's

6:41

a different solution out there

6:43

that isn't made from plastic,

6:45

and this includes our environment.

6:48

The Ojo is water encased

6:51

in a seaweed-based consumable membrane.

6:53

Might be a bit of

6:55

a surprise at first, or... a

6:57

bit confusing. Our experience has been like

6:59

we have been able to get

7:02

consumers over at hump and it

7:04

offers a very unique experience that

7:06

not many other like products really

7:08

are able to offer at the

7:10

moment especially just in the fact

7:12

that like you can eat the

7:14

entire thing. Not everyone loves to

7:16

eat the membrane but you can it's

7:18

like still a fine and pleasant experience

7:21

if you do just whatever your cup

7:23

of tea is. Removing

7:35

plastic and toxic adhesive from products

7:38

and packaging can clearly help move

7:40

us towards a world with less

7:42

waste. But Frugal Pack wants to

7:44

replace glass bottles with a more

7:47

sustainable alternative. Everyone's familiar with a

7:49

glass bottle and if you use

7:51

that same bar bottle for the

7:54

rest of your life, great, that's

7:56

absolutely fine. It's the energy that

7:58

goes into processing. processing, producing,

8:00

even recycling glass bottles is

8:03

massive. I mean glass the

8:05

melting temperature, these furnaces are

8:07

around sort of 1600 degrees

8:09

Celsius. So not only are

8:12

they massively energy heavy, but

8:14

they also are massively water

8:16

heavy in that process. John

8:19

Paul Grogan is the product

8:21

designer at Frugal Pack. back

8:25

in sort of 2013,

8:27

2014, our founder came

8:29

to myself and another

8:31

gentleman with an idea

8:34

for a bottle, a

8:36

bottle that would be

8:38

made essentially out of

8:40

printed flat sheet materials

8:42

that then could be folded

8:44

up into a 3D bottle.

8:46

The product design was

8:49

done relatively quickly and

8:51

really sort of the

8:53

last sort of Six

8:55

to eight years has been a

8:57

ring around commercializing that, turning it

8:59

from a great idea and something

9:01

that worked in a hand prototype

9:03

sense, all the way through to

9:06

sort of a production machine that

9:08

can produce 2.5 million bottles a

9:10

year for customers and we're

9:12

starting to roll those machines

9:14

out now internationally. The frugal

9:16

pack bottles are made from

9:18

a recycled cardboard bottle outline,

9:20

assembled around a plastic inner

9:23

lining. Now if you can imagine,

9:25

essentially this is a bagging box,

9:27

but it's like a bottle. If we

9:29

look at cradle to grave from

9:31

extraction of raw materials all

9:34

the way through to end-of-life

9:36

recycling scenarios, we're six times

9:39

lower than an equivalent glass

9:41

bottle. Frugal Pack's business

9:43

model is to sell the

9:45

bottle production machines to companies

9:47

who need bottles. This keeps

9:49

the production as close to

9:51

the end site as possible,

9:53

cutting down on shipping. We do

9:56

not sell them the plastic part,

9:58

the paper part, the internal... line

10:00

up out they make it using their

10:02

local supply chains so you're not

10:04

shipping stuff around you're not sending paper

10:06

around the world you're not sending

10:08

injection mold around it there's no point

10:12

so they can keep the carbon

10:14

footprint by producing locally you can

10:16

imagine storage as well it's

10:18

that versus that

10:21

so our pack density is

10:23

you know maybe 10 to 1 in

10:25

terms of what we can store in

10:27

flat pack materials compared to glass bottles

10:29

which have to be stored you're storing

10:31

air essentially with a glass

10:33

bottle. plastic

10:43

waste presents many challenges when

10:45

it's lost to the environment

10:48

it causes pollution virgin plastic

10:50

uses fossil fuel resources as

10:52

feedstock and a substantial amount

10:54

of energy in production recycling

10:56

itself uses substantial energy resources

10:59

and is inefficient murah technology

11:01

uses a different approach called

11:03

hydro prt the promises to

11:05

recycle a wider range of

11:07

plastics more efficiently with lower

11:09

energy demands dr jeff breitey

11:12

head of sustainability and rnd explains

11:14

the challenges plastic recyclers face

11:16

i think everybody has an idea

11:18

that you know we aim

11:20

to do recycling at home and

11:22

we put all the right

11:24

plastic back in the right beans

11:26

or glass or whatever but

11:28

the the sad fact is that

11:30

probably less than 10 percent

11:32

of the plastic that's ever been

11:35

produced has ever been recycled

11:37

and even then it's recycled possibly

11:39

once and then disposed of

11:41

and we're talking you know 350 million

11:43

tons of plastic being produced globally every

11:45

year you know that's less than

11:47

10 percent of that is actually recycled

11:49

that's a lot of material that's

11:51

being lost to you know the environment

11:54

and to to use as a

11:56

resource and so the challenge

11:58

is monumental firstly you've

12:00

got to capture the material back

12:02

from the waste streams. And that's

12:04

very difficult because everything is

12:07

co-mingled. But also a lot

12:09

of the plastic that's designed for

12:11

use, it's not designed for recycling.

12:13

So although the polymer is inherently

12:16

recyclable, it's in a format you

12:18

just can't get at it. And

12:20

that's particularly true with things like

12:22

flexibles. They're not very dense, they're

12:24

quite light. It needs a lot

12:27

of material to make a bale

12:29

in terms of some weight. It's

12:31

often contaminated with food, oils, other

12:33

residues. And so it's not really

12:36

suitable for what I would call

12:38

primary recycling where you're going to

12:40

bring it back into the use that

12:42

it was already doing. There are processes

12:44

for recycling plastic, but these

12:46

are limited in scale and efficiency.

12:49

There are established processes. They've

12:51

been around for a little while,

12:53

so pyrolysis being well where you're

12:55

really... shredding the plastic and having

12:57

cleaned it and then placing it

13:00

into a pyrolysis technology which converts

13:02

that plastic into a gas that's

13:04

then condensed into an oil. That

13:06

process is well established but it's

13:08

beset with a number of challenges not

13:10

the scale. These plants tend to be

13:12

on the small side. So dealing with

13:15

the 300 million tons plus of plastic

13:17

waste you can need a lot of

13:19

pyrolysis plants of sort of 3,000 to

13:21

5,000 tonne output. Typical pyrolysis

13:23

can burn plastic evenly. That

13:26

means that a lot of material

13:28

is lost as char. The process Murah

13:30

is using is hydro PRT. This

13:32

was developed in the early 2000s

13:34

by Thomas Mashmire, a

13:36

German scientist working in Sydney

13:39

Australia, to process lignite.

13:41

But Murah technology saw that this

13:43

could also be used to recycle

13:45

plastic. Supply chain stresses

13:48

during COVID and the conflict

13:50

in Ukraine, added commercial as

13:52

well as environmental impetus to

13:54

the work. does. Essentially it is

13:57

using heat so it's a thermal

13:59

process but it's also deploying

14:01

supercritical water and the

14:03

combination of the two is able

14:06

to convert that plastic waste into

14:08

a higher yield of product

14:10

at the other end and also

14:12

cleaner products as well. So heat

14:14

is applied in the process is

14:17

we're talking sort of over, you

14:19

know, about say 400 degrees C,

14:21

similar to pyrolysis. That

14:23

is helping to crack the

14:25

polymers into short chain hydrocarbons.

14:28

But what the supercritical water is

14:30

doing is essentially is creating

14:32

a reaction environment which rather

14:35

dampens down reactivity. And it's

14:37

also, because it's in a water

14:39

environment, the application of the heat

14:41

is coming via the water environment

14:43

and not directly from flame or

14:46

from direct heat. In 2024, murre

14:48

technology opened a plant in

14:50

T-side, which would prove the

14:52

technology's benefits. It offers a

14:54

range of benefits over traditional

14:56

pyrolysis. So when you separate out the

14:58

products through plasteration based on boiling

15:01

point you end up with the

15:03

water coming off but also with

15:05

some of the water soluble contaminants

15:07

that they come away from the

15:10

oil. So the process delivers a

15:12

higher yield of cleaner oils. These

15:14

can be used with fewer

15:16

additional processing steps, cutting carbon

15:19

use and improving efficiency. Other

15:21

outputs from the process can

15:23

be reused on-site. that can come

15:25

out of our hydro PRT process

15:27

range from a heavy wax residue

15:29

which is where all the the fillers

15:32

and the colorants that will

15:34

be in polymer, onmeric mixtures like

15:36

plastics and so on. They were

15:38

also additive as the system. They

15:41

will come out in that fraction.

15:43

That fraction will go off and

15:45

be used as a bitumen replacement

15:47

for road making. We then have a

15:50

range of oils from light to heavy.

15:52

depending on their saturation. And

15:54

then you also have a process

15:56

gas. Now in the first plant at

15:59

Wilton because we have no commercial

16:01

offtake arrangement for that gas that

16:03

could go off into a gas

16:05

cracker that could be readily recycled

16:07

as opposed to recovered but we're

16:09

using that that gas on site.

16:12

So it means that the the the

16:14

plants will start up on LNG

16:17

but as soon as the process

16:19

is operating a gas is being generated the gas

16:21

will then kick in and we'll be able to

16:23

reuse our gas on site. So that's a recovery

16:25

operation and that's about five percent of the

16:27

product overall. Products coming

16:29

out to the site and so our

16:31

carbon intensity overall of over our products

16:33

will then reduce by about eight nine percent.

16:36

So being able to

16:38

move to to recycle the gases that

16:40

are recovering it will also help

16:42

to reduce our carbon footprint and obviously

16:44

generate more product which is what

16:46

we want. But overall our yield of

16:48

useful hydrocarbons is above 90 percent

16:50

and you're looking at pyrolysis being in

16:52

the sort of the 50s to 60s. By

16:55

using water Murat

16:58

technology's tea side plant is in

17:00

operation with a nominal output of

17:02

20 000 tons work is

17:04

underway on other plants around the world and

17:06

the target is for these to have an output

17:08

of 50 000 tons. Magna

17:16

International is nominated in the

17:18

sustainability category for their

17:21

sustainable car door project Ed

17:23

Fortin is the global product manager

17:25

for door modules and door

17:27

systems and he's been with Magna

17:29

for 25 years. Just

17:33

a little bit of

17:35

background I did 24 23

17:37

years of engineering before

17:39

becoming the product manager and

17:41

this this idea was

17:43

really birthed when I was

17:45

still in engineering. Car

17:47

doors are made from GFPP

17:49

or glass filled polypropylene.

17:52

Presently we can recycle polypropylene

17:54

and which is the main material

17:56

we use and we can get

17:58

maybe 30 percent recycled. material into

18:00

it. It's okay. It's a

18:02

it's a nice carbon reduction. But

18:04

how do we meet the

18:06

2035 or 2050? How do we

18:08

how will we ever become

18:10

carbon neutral? Is it even possible?

18:12

And that's kind of how

18:14

it came about. So we started

18:16

looking at natural fibers and

18:18

how we can how we can

18:20

utilize those and something that

18:22

can be truly sustainable and carbon

18:24

neutral, maybe even carbon negative

18:26

if we're smart about it. Using

18:28

the natural fibers, Magna was able

18:31

to use a far simpler and

18:33

far less energy intensive process when

18:35

it came to molding the doors.

18:37

So essentially, you you have

18:40

these natural fibers that come in

18:42

huge rolls, think of like paper

18:44

rolls, you've probably seen like for for

18:46

printing presses and whatnot, the same

18:48

thing with natural fibers, we can get

18:50

the same thing, same roll. It's

18:52

thicker. And so it comes

18:54

off of there and we spray it. So

18:57

once it's sprayed and

18:59

cut, it just gets transferred

19:01

to this very small press that's heated.

19:03

It's held to 80 degrees Celsius. And

19:06

that cures it. So

19:09

it closes for maybe a

19:11

minute. And it'll cure

19:13

and we have a fully

19:15

cured part that's strong, it's stiff

19:17

and can replace polypropylene. And

19:19

so the main difference there that

19:21

I want to talk about

19:23

or would like people to know

19:25

is these injection molding machines

19:27

that we use today and polypropylene,

19:29

those are nearly 3000 ton

19:31

machines that use a lot

19:34

of energy. What

19:36

we're using now, like I mentioned,

19:38

80 just 80 degrees Celsius is

19:40

all we need. And it's a

19:42

200 ton press, not 3000

19:44

ton. So

19:47

it just benefits everywhere in terms

19:49

of our real estate that we need

19:51

in our plants, the amount of

19:53

energy we're using really gets reduced.

19:55

It's a simplified process. Not

19:58

only is the process simpler,

20:00

less energy intensive, and uses

20:02

green materials. But Magna also

20:05

found that it could improve

20:07

safety. Yeah, so the door

20:09

modules are in the side

20:11

door and can be almost

20:13

a meter square. So you

20:15

can imagine they might need

20:17

to be useful in a

20:19

side impact. So what we've

20:22

done is layered, so we

20:24

have a layer. I

20:26

guess two or three layers we can

20:28

go of the natural fibers, whether it's

20:30

jute or hemp or whatever, but in

20:33

the middle of it, we can lay

20:35

down the mesh. So we found the

20:37

flax mesh. Flax is another plant. And

20:40

it's a mesh. Think of a net.

20:42

So we put this net in there

20:44

and then we, when it all gets

20:46

layered and we spray it and go

20:49

through the same process, we end up

20:51

with a product that's 400 times stronger

20:53

impact resistance in today's product. Voudin

21:02

blade technologies is nominated for

21:04

its wooden wind turbine blades.

21:06

Tom Seekman is the CEO

21:08

of Voudin blade technologies. The

21:10

main issue is that the

21:12

blades that are currently used,

21:14

they're made of composite sandwich

21:16

materials that are very difficult

21:19

to recycle. So today 85%

21:21

of the entire turbine can

21:23

be recycled and the majority

21:25

of the 15% that cannot

21:27

is made up of the

21:29

blades. There's estimated to be

21:31

around 50 million tons of

21:33

blade material waste by 2050.

21:35

Yeah, we run some basic

21:37

feasibility checks and we've realized,

21:39

oh, it is indeed possible

21:41

to build blades out of

21:43

wood. And this was our

21:45

kind of approach to tackle

21:47

this recycling problem, as wood

21:50

is of course a natural

21:52

and regrowing resource, and it's

21:54

not fossil-based. And it hence

21:56

has... It's much easier to

21:58

decommission at the end of

22:00

its life. So this is

22:02

the kind of idea behind

22:04

why we decided to build

22:06

these blades. Voudin's blades are

22:08

made from laminated veneer lumber,

22:10

which is milled rather than

22:12

molded. It's far cheaper and

22:14

a far less energy-intensive process.

22:16

They are then coated to

22:18

protect them from the elements,

22:21

making them as durable as

22:23

existing blades, and at the

22:25

end of life, they are

22:27

completely recyclable. They are completely

22:29

recyclable. so we think that the

22:31

best uses that we use the

22:33

the the load carrying structures of

22:35

the blade and reuse them in

22:38

civil construction. The rest

22:40

of the blade could then be put

22:42

into small pieces and used as

22:45

OSB plates so it can

22:47

be reused for example in

22:49

IKEA kitchens or any other

22:51

furniture. So far Voudin has

22:53

created a prototype of the

22:55

blades which they attached to

22:57

an already existing turbine. We

23:00

managed to do so and

23:02

we also managed to certify

23:04

and install everything according to

23:07

the old construction plans. If

23:09

everything goes according to plan,

23:11

which of course we are

23:13

convinced, we are currently developing

23:15

a blade for a six

23:17

megawatt platform, which is the

23:19

state of the art currently

23:22

used in Europe. We are

23:24

planning to build that

23:27

next year and install

23:29

it that the year

23:32

after. and then once

23:35

that's proven we are

23:37

planning to commercialize the

23:40

product on a large

23:42

scale starting in 2027,

23:45

28, and then from

23:48

then on we

23:50

will hopefully see

23:53

more and more

23:55

of these wooden

23:57

turbines. He

24:00

started developing his ideas for an

24:02

improved cargo bike back in 2018.

24:04

So I looked at the current market and I

24:06

looked at the cargo bikes around there

24:09

and they're predominantly two wheel bikes with

24:11

a big gap in the middle week

24:13

and put some products in new pedal

24:15

behind it. Then these smaller vehicles appeared

24:17

in the market that had a little

24:20

box on the back of it. And

24:22

you know we are a society of

24:24

pressing a button now and getting a

24:26

parcel to the next day. and I

24:28

looked at the cargo bikes out there

24:30

and realized that not many of them

24:33

were doing the job very well. They

24:35

had very small cargo compartments so

24:37

they weren't able to carry much

24:39

product and set about designing a

24:41

vehicle that was able to carry

24:43

volume and we have the largest

24:45

now bike in the world that

24:47

can deliver four days worth of

24:50

parcels without the requirement for going

24:52

back to reload. And the fact

24:54

that it can detach and it

24:56

is a trailer means that you're

24:58

able to swap the trailers out.

25:00

So it's quite a clever product

25:02

in that respect. And then having

25:05

the digital media on board means

25:07

that there's an extra revenue stream

25:09

for the operator also. The city shuttle

25:11

approach is similar to that used by

25:14

bike rental companies like Lime. The bike

25:16

is what we call fly-by-wire. It's a

25:18

pedal assist bikes. When you turn the

25:20

pedals, the motor kicks are motor kicks

25:22

in and it assist it. We have two

25:24

to... high powered motors on board each

25:27

motor is 125 watts combined there

25:29

are 250 watts that's classification as

25:31

a bike and the pedals on

25:34

the front send a signal to

25:36

the motors but we've got 250

25:38

watts of power we've got 250 new

25:40

to meters of torque so this thing

25:43

can can really pull and that's

25:45

the thing here is the fact

25:47

that it's got the torque pulling

25:49

the pulling power to do that

25:51

so it can pull weight with

25:53

no effort whatsoever. When we interviewed Keith

25:55

in the summer, the first bikes from

25:57

city shuttle were getting out onto the

25:59

road. A passenger version of

26:01

the bikes is being developed that

26:03

would compete with taxis. We've

26:06

launched our E -PAC 4, which

26:08

is the largest cargo bike in the world,

26:11

with four cubic meters

26:13

of cargo and carrying multimedia

26:15

digital advertising on the side of

26:17

it, which we can program

26:19

remotely. And then a

26:21

few months from now we

26:24

will be launching the GECO, which

26:27

is the

26:29

taxi version of

26:31

our range. This vehicle

26:33

can carry two adults

26:35

and two children, it's

26:37

air conditioned, it's got heating,

26:40

phone charge and Bluetooth Wi -Fi, it

26:42

can travel on average a mile

26:44

in five minutes through central London,

26:46

and will be summons by

26:48

an app. Getting to

26:51

this stage was a long process, with Keith

26:53

working from his shed during Covid, as

26:55

the world went into lockdown. But

26:57

now his aim is to build

26:59

a global business. We are

27:01

looking at not just UK but

27:03

European and US manufacturing, and

27:05

we've got now founding partners on

27:07

board that want to support

27:09

that. Clean

27:17

Drive is nominated in the net

27:19

zero and sustainability categories for

27:21

their EV bus retrofits. Joe

27:25

Tai is the CEO of Clean Drive.

27:27

After a 30 year career working

27:29

in finance, Joe wanted to use his

27:31

talents to tackle big issues. And

27:34

so I felt like I really need to do something that

27:36

is impactful. I got involved

27:38

with a number of different

27:40

startups from artificial intelligence, from

27:42

drug discovery to developing a

27:45

new material to replace plastics,

27:47

using a bioplastic synthesized from

27:49

seaweed, and a

27:51

number of other things.

27:53

Joe was originally looking at energy storage

27:55

systems, which led him to speak

27:57

with bus operators. and

28:00

we came to transport and we

28:02

spoke to the bus operators and

28:04

the bus operators said, we would love

28:06

to have a micro grid and be

28:09

able to use that, but 98% of

28:11

our vehicles are still diesel. Like, you

28:13

know, it's gonna be years and years

28:15

before we can do that. And so

28:17

the light bulb moment came and I

28:19

said, okay, this is the really big

28:22

intractable problem. You've got vehicles

28:24

that live 20 to 30

28:26

years. that consume diesel, you're

28:28

never going to stop burning

28:31

diesel in the city center until

28:33

you tackle that problem. And those

28:35

assets need to be retained and

28:38

reused as clean electric. So coming

28:40

up with a system which can

28:42

scale, because there are tens of

28:44

millions of buses and trucks in

28:47

the world, and can transition that

28:49

vehicle from dirty diesel to

28:51

clean electric. in little time

28:53

and for a fraction of

28:56

the cost of replacing that

28:58

vehicle with a new electric

29:00

vehicle. If you look

29:02

at London alone, London burns

29:04

over 230 million liters of

29:07

diesel on the streets every

29:09

year. That's just London.

29:11

Imagine the amount of diesel

29:13

burning on city streets around the

29:15

world. So it gives you an

29:18

idea of the impact on society,

29:20

the impact on people's health. the

29:22

quality of life of people living

29:25

along those routes. It's all impacted

29:27

by that diesel being burned every

29:29

day, by a vehicle that passes by

29:31

every five to ten minutes. And

29:33

so it's really critical for

29:35

people's health. Clean Drive works with

29:38

bus operators to plan out a

29:40

retrofit program for all their buses

29:42

and the depot itself. We

29:44

design a system which is...

29:47

specific to the making model

29:49

of the vehicle. So we

29:51

designed a subframe. That subframe

29:54

is specific to a type

29:56

of vehicle. And then we

29:59

designed the drive train system

30:01

for the requirements of

30:03

that vehicle, which you know is to

30:05

do with the weight, the duty cycle,

30:07

and all the all the systems

30:09

on the vehicle need to be

30:11

supported. So we, the idea is

30:13

to then be able to pre

30:16

manufacture those drive trains and

30:18

work together with the fleet operators

30:20

mechanical team to apply those

30:23

that technology to the vehicle.

30:25

Clean drive has been working

30:27

with low-the-in buses. as they

30:29

begin their transition to an

30:32

electric bus fleet. So

30:34

the initial program is just

30:36

for 30. They have 750

30:39

vehicles in total. The 30

30:41

that we're repowering, we were

30:44

able to do for a

30:46

small fraction of the replacement

30:48

value. They're also buying new

30:51

electric vehicles, which probably cost

30:53

them about 25 million pounds

30:56

for those 50 vehicles. we're able

30:58

to give them 30 electric vehicles

31:00

for a much smaller amount of

31:02

money. So they're going to be

31:04

running 80 of their 750 this

31:06

year, or by the end of

31:08

next year, as fully electric. So

31:11

that has a huge impact on

31:13

Edinburgh in the town center, particularly

31:15

with the tour buses like we're

31:18

doing because they're buses that

31:20

do small circles right where

31:22

everybody congregates. So they have

31:24

an outsized impact on the

31:26

air quality gear. During

31:30

the Middle Ages the predecessors

31:32

of today's engineers sought to build

31:34

perpetual motion machines, which would

31:36

run without energy inputs. The dawn

31:39

of the modern age and

31:41

the birth of physics showed

31:43

that this would not be

31:45

possible. But an innovative approach

31:47

ABB had developed for new

31:49

cement in Turkey comes close.

31:51

Rather than running without energy inputs,

31:53

the truck they have developed takes

31:56

advantage of the site layout and

31:58

truck loads to convert... gravity

32:01

into electricity.

32:03

Thomas Huggenberger

32:05

is a product

32:08

manager for ABB. The

32:10

mining truck that we

32:13

found in this cement

32:15

plant in near Istanbul,

32:17

this is a truck manufactured

32:20

by Euclid, some 25 or

32:22

30 years old. It is

32:25

a very classic truck design,

32:27

so there is a diesel

32:30

engine of around 1,000 horsepower,

32:32

a mechanical transmission system driving

32:35

the rear axle. The vehicle

32:37

has an empty weight of

32:40

around 60 tons and they

32:42

load it when it is

32:45

full of stones, bringing it

32:47

down to the factory at

32:49

a total weight of around

32:51

180 tons. And the

32:53

interesting thing is that

32:56

the vehicle is running

32:58

upwards empty and is

33:00

running downwards when

33:02

it's full. So theoretically you

33:05

can say you should chain

33:07

energy. But up to now

33:10

it was just burning diesel

33:12

when running uphill and transferring

33:14

the energy into heat when

33:17

going down and being in

33:19

need of braking. So all

33:22

the energy. A quarry truck

33:24

like this can cost upwards

33:27

of $1.5 million, but that's

33:29

what was state-of-the-art for dump

33:32

trucks, but that's what

33:34

was state-of-the-art for dump

33:36

trucks for many decades

33:38

up to now. A quarry

33:40

truck like this can

33:42

cost upwards of $1.5

33:45

million, but as Fabiana

33:47

Caval Santé, global head

33:49

of mobile e-power at

33:51

ABB explains, The client

33:54

had other motivations to

33:56

upgrade its existing

33:58

equipment. for sustainability

34:01

so they had a

34:03

sustainability plan and they

34:05

really wanted to reduce

34:07

the CO2 emissions so

34:10

they really wanted to

34:12

of course reuse

34:15

the equipment so they

34:17

would like to prevent

34:19

it to invest this

34:21

huge capex and the

34:23

reuse because they had

34:25

like 10 of these

34:27

mining trucks so three

34:29

different mining trucks that

34:31

they would like to

34:33

to reuse and

34:35

these mining trucks they

34:37

were sorry consuming

34:39

together about one million

34:41

liters of diesel

34:43

fuel per year and

34:46

the emitting about

34:48

2500 tons of carbon

34:50

emissions per year

34:52

and this is what they

34:54

would like to eliminate

34:56

the other because they

34:58

would like really to

35:01

have zero emissions also

35:03

here and also to

35:05

have the increase efficiency

35:07

of the operation to

35:09

reduce the operation costs

35:11

so that because with

35:14

the diesel they have

35:16

higher maintenance costs and

35:18

these are like the

35:20

main goals of this project

35:22

so this is reduced

35:24

cost increase efficiency

35:27

avoid CO2 emissions

35:29

and the reuse

35:31

of the equipment

35:33

when Thomas's team became aware

35:35

of the client's needs they

35:37

jumped at the opportunity to

35:39

do something truly groundbreaking and one

35:42

of my team member he's

35:44

part of the global team but

35:46

he lives and works in

35:48

Istanbul he got aware of this

35:50

of the cement plant and the

35:52

people being interested in new

35:54

solutions they already were working on

35:56

electrification of excavators just cable

35:58

driven no batteries And

36:00

so, how the idea came up,

36:03

so why such a drug only

36:05

running downhill with the goods? Why

36:07

do we not try here something?

36:09

And when you look at the

36:12

rectification of vehicles with batteries, the

36:14

topic of the battery range is

36:16

still a very important thing. And

36:19

in this, in many cases, it

36:21

is hindering. So you always have

36:23

to find the use cases where

36:26

the batteries can perform well and

36:28

you get a... with for example

36:30

with small battery a very nice

36:33

system and so that the more

36:35

we looked at it and the

36:37

more simulations we did the more

36:40

it turned out that this is

36:42

something that really should be looked

36:44

at and yeah finally being executed.

36:47

The initial project with new required

36:49

the application of a range of

36:51

existing ABB E mobility technologies but

36:54

it's now ready to be implemented

36:56

on suitable sites around the world.

36:58

But for sure there was a

37:00

lot to do to take this

37:03

originally a combination of parts. It

37:05

is a motor from a very

37:07

large locomotive, a converter from a

37:10

bus and a battery from a

37:12

passenger train, at least at the

37:14

first view, but to... to redesign

37:17

and shape it and understand the

37:19

application, the interface of the vehicle,

37:21

that was still a long way.

37:24

But at the end it was,

37:26

or at least for future projects,

37:28

that should be something which is

37:31

a relatively easy swap in the

37:33

way. One

37:40

of the hardest sectors

37:42

to decarbonise will be

37:45

aviation. This is the

37:47

market Avioxx is targeting,

37:50

with a new approach

37:53

to producing sustainable aviation

37:55

fuel. Chief Technical Officer

37:58

Steve Wilkinson explains. to

38:00

demonstrate turning waste into jet

38:03

fuel. That's our mission. And

38:05

we're looking at the scale of

38:07

production. Yeah, so the process

38:09

for turning waste into jet

38:11

fuel is actually quite simple

38:13

in its essence. It involves

38:15

two steps in our process.

38:18

So it involves taking anything

38:20

that will burn. So plastic

38:22

and carbon in waste, for

38:24

example, non-recitals. and then partially

38:26

combusting that with less oxygen

38:28

than it needs to form

38:30

CO2. And then it forms

38:32

processes called gasification, and then

38:35

it forms something called sin

38:37

gas, which is carbon monoxide

38:39

and hydrogen. And then we

38:41

take that sin gas, clean

38:43

it up, and then react

38:45

over a catalyst called the

38:47

Fichotrop synthesis, where we make

38:49

hydrocarbons. Those hydrocarbons are mixed,

38:51

just like crude oil, and

38:53

heavy hydrocarbons, lighter ones. and

38:55

then we can upgrade that

38:57

fuel just like in all

38:59

refinery would do using distillation,

39:01

hydro cracking etc to make

39:03

the product they're interested in

39:05

which is essentially C9 C16

39:07

range nine carbon atoms up to

39:09

16 carbon atoms and that is

39:11

the the fraction that is commonly

39:14

called kerosene and that's what jet

39:16

fuel is. Avioxx believes that

39:18

its approach offers real benefits

39:20

over others that are currently

39:22

in development. So there are other

39:24

people doing the same process. We

39:27

have an innovative process flow sheet.

39:29

So in our case, we can use some

39:31

of the sin gas which has energy in

39:33

it, pass that over a solid oxide

39:36

fuel cell, or some other

39:38

means of making electricity. And

39:40

then we can use that electricity

39:42

to split water to make hydrogen

39:45

and oxygen. The oxygen we

39:47

can use for the gasification because

39:50

that makes the gasification

39:52

more efficient. and then we

39:54

can use the hydrogen to top

39:56

up the sin gas because the sin

39:58

gas roughly is... equal hydrogen

40:01

to carbon monoxide when

40:03

it's made, but we need two

40:05

molecules of hydrogen for each

40:07

molecule of carbon monoxide for

40:09

the fish atrops process to

40:11

make hydrocarbon, CH2. So we use

40:13

the hydrogen for explicit water

40:15

to top of the sin gas. So it's

40:17

a very effective process flow sheet

40:20

where we make the best of the energy

40:22

value in the waste to make the

40:24

maximum amount of product. The other

40:26

thing about the process is dealing with

40:29

the waste. As obviously as

40:31

you might imagine the waste is

40:33

quite non-uniform in its composition

40:35

and so we have quite another way

40:37

of dealing with the waste to make

40:40

it more uniform. We basically sort

40:42

it and then blend it back

40:44

together again according to a recipe

40:46

that we've established and that

40:48

makes a more consistent fee stock

40:51

for the gasifier. The process that

40:53

Avioxx has developed is based on

40:55

a patent held by its chairman

40:58

Mike Hancock. Both Mike

41:00

and I have known each other for

41:02

quite a while. We're both chemical engineers

41:05

and Mike actually did some work

41:07

on pre-combustion carbon capture.

41:10

So Mike is an energy

41:12

consultant. He's an expert in the

41:14

area of low carbon clean energy

41:16

from hydrocarbon. So

41:18

he actually patented a process

41:20

but 11 or 12 years ago now

41:23

that's the front end of our

41:25

process. So that's the bits that's

41:27

the bits that using some of the

41:29

energy in the sin gas to split water. I

41:31

never completely understood his pattern until

41:33

we actually decided to go for

41:35

this and then we realized that

41:38

we could apply this to sustainable

41:40

aviation fuel because that's the front

41:42

end of our process. So that's how we

41:44

got here. And the pattern, it's not a

41:46

pattern for a particular, it's a

41:48

particular reactor or gas device, a piece of

41:50

equipment. It's a path for the process.

41:53

So it's actually quite an achievement to

41:55

get a passion. for a novel

41:57

configuration of existing

41:59

units. So we've not developed

42:01

new units in the process ourselves, we

42:04

just configured them more efficiently we think.

42:07

If Aviox can scale its process

42:09

up, it could revolutionise the

42:11

aviation industry. Because the big problem,

42:14

sustainable jet fuel looks

42:16

like it will be expensive to make. So

42:19

the business that can make it for the cheapest

42:21

price, I think it'll be like a winner takes

42:23

all. Well if we can, our aim

42:25

is to make sat sustainable aviation

42:27

fuel from waste at

42:29

a price that's similar to what

42:31

to the cost that it is now

42:33

from fossil based sources. And if

42:35

we can do that, I think we will

42:37

have a real competitive advantage. And

42:40

it means that this

42:42

technology can be adopted more widespreadly. Vertical

42:50

Solar is nominated in

42:52

the net zero category.

42:54

Maurice Briggs is the

42:56

CEO of Vertical Solar.

42:58

So we are the

43:00

leaders in making enclosures

43:02

from solar panels. This

43:05

could be something that's a

43:07

rectangular enclosure or something that's

43:09

more interesting in octagonal or

43:11

other geometric form. And we

43:14

found they're very good for

43:16

powering equipment in the winter.

43:18

They outperform angle panels. And

43:20

they're very good for increased

43:22

generation yields in a constrained

43:24

or confined space. Angled

43:27

solar panels are the best positioning

43:29

for a single solar panel. But

43:31

the combined output of five solar

43:33

panels arranged around a box of

43:35

the same surface area is more effective.

43:37

First of all, through the year,

43:39

you get in this country, you get

43:42

sort of two and a half

43:44

to three and a half times the

43:46

solely yield of those panels, you

43:48

know, as if there are angle panels,

43:50

which would occupy the same volume.

43:52

And that's important. But

43:54

more importantly, you

43:56

get sort significantly better

43:59

yields in. indirect radiation so

44:01

when there isn't direct sunlight in

44:03

the UK that's pretty much half

44:06

170 days it's kind of half

44:08

the year so there's an argument

44:10

that we should we should just

44:12

be designing for that anyway you

44:15

get better direct better indirect yield

44:17

and you get as a say

44:19

when the energy is most valuable

44:22

in the winter and the sun

44:24

is lower in the horizon you

44:26

get improved direct yields. Inside the

44:28

box, a battery to store the

44:31

energy is housed, making vertical solar

44:33

boxes perfect for remote locations that

44:35

require low levels of consistent power.

44:38

So we were approached by one

44:40

of our customers to... So our

44:42

customers are water utilities and they

44:45

have a requirement to check the

44:47

quality of water, more or less,

44:49

anywhere where there's a buildup

44:51

of population, so villages town

44:54

cities. and to do that

44:56

they run some water and

44:59

conduct some tests and sample

45:01

it. But obviously they can't

45:03

do that if all the

45:06

water is frozen. And if

45:08

that that sort of goes

45:10

on for some time that

45:13

can be quite problematic because

45:15

they just don't know if

45:17

the water's okay and that's

45:20

obviously not a good place

45:22

to be. So this is

45:25

downstream from a water processing

45:27

facility just... upstream from the

45:29

Glen Livot estate in Scotland.

45:32

So this is the water

45:34

quality sampling point just before

45:36

the distillery. And for I

45:39

think at least 20 years

45:41

every winter, they can be

45:43

minus 20 degrees Celsius outside.

45:46

It got to minus 17

45:48

this year. And so they

45:51

wanted a solution off-grid that

45:53

stopped the internal freezing. heating

45:55

with vertical solar arrays facing

45:58

north in the winter. So,

46:02

yeah, we sized and designed,

46:04

there's retrofit and stuff internally,

46:06

so there's a low energy

46:08

output heater so it won't

46:10

burn anyone, and

46:12

so the consumption is sort of manageable. Yeah,

46:15

and we sized, insulating

46:18

that enclosure and

46:20

sized what we thought the solar would achieve.

46:23

We couldn't put a panel on the

46:25

door because the door was too small and they

46:27

can only use certain panel types for

46:29

human reasons, so it's very constrained, but

46:32

yes, we found that for the first

46:34

year, and it's actually featured in

46:36

their annual report, they've been able

46:38

to sample at that site year round,

46:40

which is just ludicrous, it

46:43

shouldn't work, it's heating

46:45

with suboptimal vertical solar. SDP

46:53

has nominated in the net zero

46:55

and sustainability categories for their

46:57

canopy solar farms. Alf Oschatz is

46:59

the Managing Director of SDP. It's

47:02

a very efficient

47:04

lightweight solution, and

47:07

by reducing the material

47:09

used for the PPV,

47:11

our Parkplatz PV or

47:13

Acre PV solutions, we

47:15

reduce the carbon footprint

47:17

and we also reduce

47:20

the operating cost. SDP

47:23

aims to minimize the materials used in

47:25

the construction of a canopy solar

47:27

farm over agricultural land or a car

47:29

park. SDP solar car

47:31

park is usually

47:33

based on a

47:35

column and beam

47:38

system with some

47:40

cantilever arms, there

47:42

are structural requirements,

47:44

they are relatively

47:46

heavy and bulky,

47:48

and we have

47:51

replaced the structure

47:53

system by a very

47:55

lightweight system of

47:57

primarily of the

48:00

We start relatively early

48:02

to collaborate and to optimize and

48:04

by doing this we can

48:06

reduce the weight and the

48:08

volcanoes of the system. SDP

48:10

uses a modeling software

48:12

in collaboration with their clients

48:15

to optimize the solar canopy

48:17

farm design to client specifications.

48:20

We start relatively early

48:22

to collaborate and to

48:24

optimize. to optimize our

48:27

solutions to tailor it

48:29

more towards the manufacturing.

48:31

So we have manufacturing

48:34

partners, but then we

48:36

are obviously also capable

48:38

and interested in work

48:41

with clients to understand

48:43

their specific needs. And

48:45

for example, if

48:48

it's about the agricultural PV,

48:50

then some clients want to

48:53

have. say 25% and others

48:55

want to have 75%

48:57

ground coverage. Some people

49:00

want to have or

49:02

are aiming to get

49:04

a power park solution

49:07

which leaves space in

49:09

between four roads. Others

49:12

may park, park, car.

49:14

next to a car next to

49:16

a car next to a car

49:18

to to they want to have

49:20

a full coverage so they're always

49:22

there always possibilities to use our

49:24

our concept as a base but

49:26

to adopt it to a specific

49:28

to a specific use case similar

49:31

to any construction project

49:33

which is always in a

49:35

construction project you have all

49:37

this say standards and then you

49:39

have to adapt to a specific

49:42

to a specific to a specific

49:44

need. Water

49:49

safety or the lack of

49:51

it is becoming an increasing

49:53

threat around the world and

49:55

protecting waterways from pollution and

49:57

water systems from leaks and

49:59

defects. is critical to maintaining

50:01

people's access to clean water.

50:03

Gorilla is nominated in the Environment

50:06

category for its device that prevents

50:08

pollution and run-offs entering waterways through

50:10

drainage systems. Addis Shenoy is one

50:13

of the co-founders of Gorilla. So

50:15

guerrilla is a startup where we

50:17

are creating these devices that go

50:19

into roadside drains and captures pollution

50:22

that gets washed away every time

50:24

it trains in the urban environment.

50:26

So yeah, there's a whole bunch

50:29

of research to prove that almost

50:31

30% of ocean pollution is actually

50:33

mobilized by this mechanism that's called

50:36

runoff, but yet not much is

50:38

being done on it. So we've

50:40

tried to create like a retrofitable

50:42

device to reduce a barrier for

50:45

entry for instant. following it in

50:47

urban landscapes. Guilla was started when

50:49

the co-founders came together as part

50:52

of a joint degree between the

50:54

Royal College of Art and the

50:56

Imperial College of London, where they

50:59

were doing a master's programme in

51:01

innovation, design and engineering. as

51:04

part of that degree. We

51:06

had quite an open-ended brief

51:08

and we started looking at

51:10

and that was about the

51:12

time where they discovered polio

51:14

in the wastewater that comes

51:16

out of cities. And that's

51:18

when we started looking at

51:20

wastewater and the topics surrounding

51:22

wastewater. And that's when we

51:24

realized that actually not much

51:26

is being done with runoff

51:28

in particular, even though it's

51:31

such a huge contributor to

51:33

water pollution and ultimately ocean

51:35

pollution. So there are two

51:37

angles to this one being

51:39

that a lot of the

51:41

treatment happens at treatment facilities

51:43

where like like you mentioned

51:45

there's a lot of chemicals

51:47

that that are involved that

51:49

electricity and the costs involved

51:51

with run of treatment are

51:53

quite significant so much so

51:55

that quite often right now

51:57

you would have come across

51:59

this in the news where

52:01

what companies are just dumping.

52:03

run off along with sewage

52:05

many times into water bodies

52:07

just because it's cheaper to

52:09

do that rather than actually

52:11

treated. And then the second

52:13

half of this problem is

52:15

actually that there are regulations

52:17

that are coming about from

52:19

the Suds point of view

52:21

and Suds is sustainable urban

52:23

drainage systems. So you have

52:25

things like permeable pavements or

52:27

green spaces where people have

52:29

started installing things like these within

52:32

their place of. that area. And

52:34

the problem with that is that

52:36

a lot of these chemicals that

52:38

are present in run off things

52:40

like heavy metals, toxic hydrocarbons, they

52:42

get trapped within these permeable pavements,

52:44

but also these green spaces, and

52:47

you're not able to actually extract

52:49

them out. So essentially you're creating

52:51

like a mini landfill within the

52:53

urban environment. In the short term,

52:55

it works, but over duration, it's

52:57

not a viable solution, because you're

53:00

not able to actually extract

53:02

these chemicals. The solution that

53:04

guerrilla produced works with no

53:06

chemicals and no power and

53:08

can be retrofitted directly into

53:10

existing roadside drains. So

53:12

essentially it's easiest to imagine it

53:15

as a bunch of tubular units.

53:17

So they're an array of individual

53:19

units that go together and usually

53:21

if you imagine a roadside drain

53:23

that you would have seen on

53:25

any on any road per se.

53:27

These units normally it's a set

53:30

of three cross three so you

53:32

have nine units that go into

53:34

that roadside drain. So essentially inside

53:36

each tubular unit we have an

53:38

internal geometry that leverages centrifugal separation

53:41

but also capital reaction. So we

53:43

use these two physics principles to,

53:45

it's quite a simplistic design in

53:48

the way that you don't have

53:50

macrodabe that gets caught within, but

53:52

then you have these micro particles

53:54

that actually fall to the bottom

53:57

while cleaner water is left back

53:59

outside. Guerrilla has been working

54:01

with the office of the Mayor of London

54:03

and has begun trials with its system in

54:05

drains around West London. FIDO

54:12

AI is nominated in the sustainability

54:14

and environment categories for their

54:16

work using AI and acoustics to

54:18

detect leaks in water systems. I'm

54:24

Victoria Edwards, I'm the CEO and

54:26

co -founder of FIDO Tech. And

54:29

if you had to describe

54:31

FIDO Tech, we are AI, water,

54:35

impact, and that's climate impact,

54:37

social impact and economic

54:39

impact. We live in a

54:41

world where we are facing

54:43

water scarcity by 2030. There'll be

54:45

a 40 % increase in demand

54:48

against availability. As a result

54:50

of that, we're seeing a 500

54:52

% increase in more related conflicts

54:54

since 2010. We're seeing a

54:56

6 % GDP reduction where there

54:58

is no water available and yet

55:00

one in two of us

55:02

face water stress for one month

55:05

of every year. This is

55:07

a global problem. Around the world,

55:09

water systems are struggling. 30 %

55:11

of water being delivered through these

55:13

systems is lost through leaks. That

55:16

is unconscionable. No

55:19

other industry, you can't imagine Mercedes

55:21

building 100 supercars and then burning

55:23

30 on the four -court. But this

55:25

happens and it's been happening for

55:27

decades. So we've got this gap

55:29

between supply and need and yet

55:31

we're losing everything. And the reason

55:33

for that is leaks are really

55:35

difficult to find. Only, you know,

55:37

the ones you see gushing down

55:39

the street and everybody's up in

55:41

arms, that's only 5%. 95 %

55:43

of leaks never appear above ground. FIDO

55:47

partnered with Microsoft and Thames Water

55:49

to use their technology to

55:51

identify leaks in London's water system.

55:54

So we started actually in Thames, which is

55:56

one of the most difficult networks in the world,

55:58

with Microsoft. Fido

56:00

analyzed 35 ,000 historic acoustic files

56:03

in just two and a

56:05

half hours and with a

56:07

92 % accuracy they identified 20

56:09

leak sites that could then be

56:11

repaired. They gave us 350

56:13

kilometers of the network for 10

56:15

years and said actually right Fido

56:17

come in run this Fido plus

56:19

project drive down the leakage we'll dig

56:22

the large ones we'll monitor your monitor

56:24

the smaller medium ones we'll check the

56:26

outbreak and each individual leak event has

56:28

got an audit trail so when we

56:30

went we took the GIS map and

56:32

off we go and we

56:34

can stand behind every single

56:36

leak that we said has been verified. Fido

56:39

set a target in their first year

56:41

monitoring hundreds of kilometers of pipe

56:43

in London to save three billion gallons

56:45

of water. We had

56:47

a contractual commitment with Microsoft we thought we

56:49

did an assessment of the network in

56:51

terms and we said we think we're going

56:53

to save this much water we're at

56:55

146 percent of

56:57

target on the first year

56:59

and that's all being independently verified both by

57:01

TEMS and by Limitech and we do the

57:03

same in every project with every corporate that

57:05

we work with. That's

57:08

nearly four and a half billion gallons

57:10

saved in one city in just

57:12

one year and what we're

57:14

doing with that data is we're feeding it

57:16

back to the utilities to say actually now you

57:18

can see last last March how many new

57:21

leaks appeared what size were they how long

57:23

did they take to degrade so they're getting truth

57:25

data to put to help them

57:27

make decisions about capital

57:29

rehab about capacity

57:31

planning based on actually

57:33

actions that have seen have happened

57:35

and that's quite rare to see that.

57:38

Fido is also nominated

57:40

in the community and environment

57:42

categories for their work

57:44

setting up water united and

57:46

we're just about to do our big one called

57:48

water united when we said okay let's do this

57:50

at scale bringing lots of other corporates in to

57:53

take on the colorado river basin and the Fido

57:55

AI model that just is now currently looking

57:57

at the clean water network is going to

57:59

build out to create

58:01

a healthy watershed AI model

58:03

for the future that pulls

58:05

in river abstractions, stormwater, waste

58:07

water, water, aquifer recharge, built

58:10

on the model that we

58:12

built that four and a

58:14

half years ago, standing in

58:16

Wigan, and I was saying,

58:18

let's actually attack leakage. And

58:20

that's the power of us,

58:23

we'll bring in other technologies,

58:25

and we'll verify their data,

58:27

and we'll take it in.

58:29

And we finally stand a

58:31

chance by creating these catalytic

58:33

communities, powered by the corporates,

58:35

working with the communities together.

58:38

to hopefully help create a

58:40

world without water scarcity. Engineering

58:42

Matters is a production of

58:44

Reby Media. This episode was

58:46

written and produced by Johnny

58:48

Dowling and Will North, with

58:51

additional research by Alex Antonio.

58:53

It was hosted by me,

58:55

Alex Conica, and also by

58:57

Johnny Dowling, series supervision by

58:59

John Young. Sound Engineering by

59:01

Ross MacPherson, and the man

59:03

who ensures we transform words

59:06

into reach, without waste, is

59:08

Rory Harris. Thank you for

59:10

listening. You can find us

59:12

on all podcast apps on

59:14

our website, Engineering matters.org. media,

59:16

and on LinkedIn.

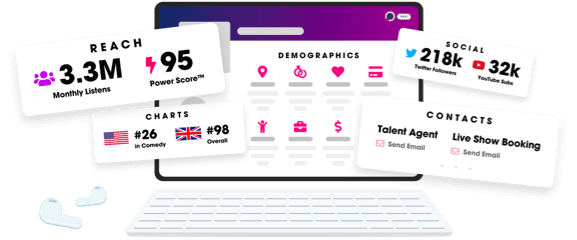

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us