Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Wondery Plus subscribers can listen to how

0:02

I built this early and ad-free

0:04

right now. Join Wondery Plus

0:07

in the Wondery app or on Apple Podcasts.

0:09

Are you building a business? Achieving

0:12

security compliance can help you win bigger

0:14

deals, enter new markets, and

0:16

deepen trust with customers. But

0:19

it can also cost you real time and

0:21

money. Vanta automates

0:23

up to 90% of the work needed for

0:25

SOC 2,

0:25

ISO 27001, HIPAA, and more, saving

0:31

you hundreds of hours and up to 85% of

0:33

associated costs. Join 6,000

0:37

fast-growing companies like Chili Piper,

0:39

Patch, and Autodesk that use

0:41

Vanta to manage risk and prove security

0:44

in real time.

0:45

Watch Vanta's on-demand demo at

0:47

vanta.com. Plus, you'll be able to

0:50

claim a special offer of $1,000 off Vanta. That's

0:58

V-A-N-T-A dot com slash built.

1:01

This episode is supported by Trustonomy,

1:03

an original podcast from OneTrust. Every

1:06

good relationship you have, personal

1:08

or business, involves trust. Sharing

1:11

a secret with a friend, using an app,

1:13

or getting in a vehicle. In each of those

1:15

scenarios, you're trusting that you

1:18

and your information are going to be safe and protected.

1:21

But we all know that doesn't always happen.

1:23

We've all lost trust in a friend, a brand,

1:26

or a product. Trustonomy is

1:28

a new podcast that looks at true stories

1:31

from the past to understand how trust

1:33

works, what makes it stronger, and

1:35

how to rebuild it when it's broken. Search

1:38

for Trustonomy in your podcast player.

1:40

My thanks to OneTrust for their support.

1:59

the Time is Now Sale. Order

2:02

your at-home impression kit today for just $14.95, save $250 on

2:04

clear aligners, get $120

2:09

off the Bite Protection Plan, and claim a

2:11

free LED whitening kit

2:12

worth $150. Use

2:14

code NOW23 at Bite.com. That's

2:17

B-Y-T-E dot com. Plus

2:19

you can upgrade your oral care routine with 25%

2:22

off best-selling wellness, whitening, and cleaning

2:24

essentials. Be confident. Be you.

2:27

With Bite.

2:29

Hello and welcome to How I Built This

2:32

Lab.

2:32

I'm Guy Raz. So when it

2:34

comes to carbon emissions, there are, you

2:36

know, the usual suspects we hear about all the time.

2:39

Fossil fuels, livestock, transportation.

2:43

But there are other sources of carbon emissions

2:45

that are less flashy but just as impactful

2:47

on our climate, including a material you

2:50

might be standing on right now, which is

2:52

cement. Yes, cement. We

2:54

use it to glue together just about everything

2:56

we build, but the production of cement

2:59

worldwide actually emits almost

3:01

as much carbon as cars do. The

3:04

majority of that carbon comes from one of

3:06

the main ingredients in cement, which

3:08

is limestone. To make

3:10

cement, you basically cook limestone

3:13

at high temperatures. But limestone

3:15

is actually a carbon sink. It

3:17

contains a lot of carbon, and when you heat it up

3:19

to make cement,

3:20

that carbon is released into the atmosphere.

3:23

Well, my guest today says there's

3:25

another way to make this critical building

3:27

material. Cody Finkie discovered

3:29

the concrete problem when he was studying

3:31

chemistry at Caltech. He

3:33

realized there was a different rock that

3:35

could replace limestone in concrete

3:38

production. It's a rock that really

3:40

doesn't emit any carbon when heated.

3:42

And so Cody co-founded a company called

3:45

Brimstone that could become the

3:47

future of construction materials. Cody

3:50

spent his time at Caltech looking for a climate

3:52

issue to solve, and he started with solar-powered

3:55

toilets. I wanted

3:57

to work on problems that were...

3:59

massively underworked on, had environmental

4:02

and social implications, and

4:05

wastewater treatment for applications in low-income countries

4:08

was an obvious choice. And

4:10

that was something that one of the labs at Caltech

4:13

was working on. So I enthusiastically joined that

4:15

lab. I done travel in

4:17

India and seen that firsthand and

4:19

how it impacted people. And

4:21

the idea was we'd build a

4:23

system that didn't need a sewer, didn't need

4:25

a grid, is just fully independent

4:28

and treated wastewater on site. But

4:31

through that project, I also learned

4:33

that deploying these sort of do-good

4:36

technology is not trivial, because

4:38

people don't just buy them and install

4:40

them out of the goodness of their heart, or at least

4:42

not enough. There needs to be a compelling

4:44

economic case. And after

4:47

three or four years of working on that solar-powered

4:49

toilet system, I realized that there just

4:51

wasn't a compelling economic case. And therefore,

4:54

no matter how well the technology worked, it

4:56

was not going to make an impact. This couldn't

4:59

be a sustainable business, as you

5:01

kind of got to that conclusion. That's

5:03

right. And if it's not a sustainable business,

5:06

then it's also not going to have the environmental

5:08

impact I wanted to have, because it just isn't going to achieve

5:11

the scale.

5:11

This project that you worked on, I mean, it won

5:14

an award from the Bill and Melinda Gates Foundation.

5:16

So I mean, it was no joke. I mean, this is a serious,

5:19

and essentially, it worked, right? I mean, what you

5:21

put together worked.

5:23

Yeah, I spent a lot of time in India sort of wallowing

5:26

around in human wastewater as I was working

5:28

on that project. And yeah, it worked.

5:30

So you ended up continuing

5:32

your studies at Caltech, and you did your PhD

5:34

there. Yeah. And I guess while you

5:37

were there, after that project,

5:40

you decided to tackle another

5:43

project around water electrolysis. Can

5:45

you tell me a little bit about what that project was?

5:47

Yeah. So

5:49

after this solar-powered toilet situation,

5:52

I was looking around for what else to do.

5:55

And a lot of folks at Caltech were working on splitting

5:58

water in order to replace fossil fuels. And

6:00

the idea was we could use clean renewable electricity,

6:03

split water into hydrogen and oxygen, and

6:06

then use that hydrogen as a fuel

6:08

to fuel everything we do today, and we wouldn't have

6:10

to use any fossil fuels. And the

6:13

scale of that solution was really compelling to me.

6:15

That's 70% of greenhouse gas emissions. But

6:18

I realized that the technology

6:20

had been around for over 100 years, and

6:23

we don't make hydrogen by splitting water today. We

6:25

make hydrogen a different way from a

6:27

fossil fuel, actually. And we do that because

6:30

it's the lowest cost way to make hydrogen.

6:33

And I didn't see a route

6:35

for hydrogen production

6:38

to become lower cost than the production

6:40

from fossil fuels. And therefore, ultimately, I didn't

6:42

see a chance for there to be a big

6:45

impact. So I ultimately stopped working on

6:47

that project too.

6:48

But clearly, you were thinking of

6:51

a project that you could get behind.

6:53

I guess the question you're asking yourself is, what are the things

6:56

that create carbon emissions? It's

6:58

interesting because it's a similar question that Pat Brown

7:00

asked himself before he started Impossible

7:02

Foods. And his realization

7:05

was, you know, raising livestock,

7:07

right? Clearing forests to create grazing

7:10

spaces and raising livestock for

7:12

human consumption, you know, accounts

7:15

for 15% of global carbon emissions.

7:17

Presumably, you're asking yourself the same questions. What

7:19

are the things that cause

7:22

the most pollution that I might be able to fix? So

7:25

what kinds of industries or

7:28

materials are you looking at?

7:30

Yeah, so I found

7:33

this really interesting graph from

7:35

the IPCC report. I think

7:37

it was... This is obviously the UN Panel on

7:39

Climate Change. Exactly, the Intergovernmental Panel

7:42

on Climate Change, the IPCC. And

7:45

this graph kind of broke down emissions by sector.

7:48

What really attracted me were the chemistry problems,

7:50

because I have a chemist. And

7:53

there are several categories that have

7:55

these things called process emissions, where

7:58

the chemical reaction we use... to

8:00

make the thing actually

8:02

emits a greenhouse gas. It's

8:04

not just energy, it's the chemical reaction.

8:07

And

8:08

the four big ones are

8:11

production of steel,

8:12

production of aluminum, production

8:14

of hydrogen actually, and then production

8:16

of cement. This is a huge problem.

8:19

I then looked at the amount of funding, right?

8:22

And one metric that was really interesting

8:24

to me was the dollars invested in decarbonizing

8:27

the product per ton of greenhouse gas

8:29

emissions.

8:30

And I couldn't really find anything lower than cement.

8:32

It's interesting because I guess concrete and cement

8:35

are, they're slightly different. That's right.

8:37

Concrete is a product that comes from cement.

8:39

That's right. But together they account for like 8%

8:42

I read of global CO2 emissions, which is

8:44

the same amount as all the cars around the world.

8:47

Yeah, just about the same. Yeah. And just

8:49

to clarify the cement and concrete, concrete

8:51

is the building material and cement is

8:53

the binder and the glue. Yeah. And

8:56

about 90% of the emissions come from

8:58

cement. Yeah. And I mean, it's amazing

9:00

because cement is critical.

9:02

We need this

9:05

building material to build on planet

9:07

earth. And so it seems like

9:09

a kind of intractable problem, right? But it's not like,

9:12

I mean, even fossil fuels, there's a backup,

9:14

right? With renewables, but with cement, there's

9:16

no easy backup. I

9:18

mean, this is what you're sort of discovering, I guess,

9:21

in 2015, 2016, when you're

9:23

looking into it. That's right. I actually,

9:25

I

9:26

really liked that because it made the solution

9:28

space really simple. And I think you need to simplify

9:32

the solution space in order

9:34

for a human brain to be able to think

9:36

about it creatively. So yeah, that was one of

9:38

the things that attracted to me, how simple the solution

9:40

space was. All right. So let's break down the problem.

9:42

Why does cement

9:44

create so much carbon emissions?

9:46

Yeah. So the emissions

9:49

associated with cement production come from

9:51

two places. The first is

9:53

you need to burn a lot of fuel

9:55

because you need to use a lot of energy to

9:58

make cement. And that's about 40%. percent of

10:00

the emissions in cement production. To heat

10:02

it up very hot. Yeah, you have to do

10:04

a chemical transformation, and that chemical reaction requires

10:07

heat or requires energy. And by the way, the

10:09

main component is limestone? That's

10:12

right. So that's where the majority of the emissions come from.

10:14

So in order to make cement,

10:17

you need a source of calcium. And

10:19

the current way we make cement, that source of calcium

10:21

is limestone. Because

10:24

why? Because at the time that cement was invented, it was

10:26

the lowest cost source of calcium.

10:29

And this isn't like the 1700s, I think. Different

10:32

people have different timelines, but yes, like the first

10:35

poly-calcium silicate cement was in

10:37

the 1700s. And

10:39

so limestone was used because it

10:41

was readily available and relatively cheap, and now

10:44

that's just the standard. That's right.

10:46

And in order to get the calcium

10:48

out of the limestone, you use all that

10:51

heat to do a chemical transformation which

10:53

removes the CO2 from the limestone. And

10:56

if you use heat, all that CO2 will go up into

10:58

the atmosphere and you'll be left with the calcium

11:00

that you can then turn into Portland cement. Wow.

11:03

So basically, it's like a double whammy. You're

11:06

using heat to heat it up, and the heat,

11:08

just that energy alone is emitting carbon.

11:11

But then there's also carbon dioxide in

11:13

limestone. So when you heat the limestone

11:16

to break it down, you're releasing all that carbon

11:18

into the atmosphere.

11:19

That's right. And the majority of the CO2 emissions

11:22

from cement come from that chemistry for

11:24

releasing the CO2 from the rock. So

11:26

limestone is a carbon sink, basically.

11:29

That's right. Yeah. So

11:31

in the global carbon cycle, an enormous amount of Earth's carbon

11:33

is stored in limestone. Wow. So

11:36

this is... It's like you hear about the tundra,

11:38

the tundra that's defrosting and the

11:40

Arctic, and that's a carbon sink. And obviously, when

11:42

it defrost, it releases carbon. So this is

11:45

a deliberate process to make cement, but it's

11:47

essentially just releasing all this carbon,

11:50

which is a huge problem.

11:53

That's right. Yeah. It's

11:55

just another way that humans are perturbing the global

11:58

carbon cycle in a normal environment. environmental

12:00

carbon cycle, CO2 would be released

12:02

from volcanoes and would

12:05

react with calcium that's been dissolved in the

12:07

ocean and precipitate limestone. And

12:09

then that limestone would sit around forever for

12:12

several billion years until it was subducted down

12:14

to the Earth's crust again and then decomposed

12:17

under the Earth and the CO2 was released through a

12:19

volcano.

12:20

And humans, by digging

12:22

up limestone and heating it up to volcano

12:24

type temperatures, we release that

12:26

CO2 prematurely which perturbs

12:28

the carbon cycle just like with fossil fuels. Wow.

12:32

All right. So when you came across

12:34

this realization, I presumably

12:36

you thought this is the thing. Maybe

12:38

this is the thing that I can try and fix.

12:41

Yeah, it's quite interesting. It had all the attributes,

12:44

right? It was the giant problem. Basically

12:46

nobody was working on it and it was tractable

12:49

to me because it was a chemistry problem. The

12:51

chemistry problem was most of the CO2 missions have nothing

12:53

to do with energy. They have to do with the chemistry of making

12:56

cement. So can I change the chemistry such

12:58

that it doesn't make CO2 missions? We're

13:01

going to take a quick break, but when we come back, Cody

13:04

finds a solution to that chemistry

13:06

problem right beneath his feet. Stay

13:08

with us. I'm Guy Roz and you're listening to How

13:10

I Built This Lab.

13:16

Hello everyone. I've been working with Miro,

13:19

that's M-I-R-O, over

13:21

the last year to help me get a better sense

13:24

of what you, our incredible listeners,

13:26

are thinking. Miro has sponsored quite

13:28

a few of our episodes and it's just an amazing

13:31

tool for collaboration and working with teams.

13:34

If you haven't heard of it, Miro is this incredible

13:36

online workspace and I think it's super

13:38

useful to try it out if you want to build something great

13:41

with your team. Now I want to talk about a part

13:43

of Miro that many of you probably have never

13:45

heard of before. It's called the Miroverse.

13:48

Sometimes starting work on an online visual workspace

13:51

can feel overwhelming. But with Miroverse,

13:54

you can select pre-made boards

13:56

for pretty much any use case. It

13:58

saves you the hassle of it. of building from

14:00

scratch. And what's really cool is that a new

14:03

template has just been added, this time from me.

14:05

We partnered with the folks over at Miro to

14:08

create a how to build a podcast

14:10

Miroverse template to help kickstart

14:13

your journey to making a podcast. So

14:15

check it out and let me know what you think. Head on

14:17

over to miro.com slash

14:20

h-i-b-t. That's m-i-r-o.com

14:23

slash h-i-b-t to

14:26

check out our Miroverse template for

14:28

yourself. Spectrum

14:30

Business is made to work the way small business

14:32

works. Made to rise and grind.

14:35

Made to start small, but think big.

14:37

Made to do this and that all

14:39

at once. And made to do it all with fast,

14:42

easy to use, ultra reliable internet,

14:44

phone, and mobile services. Working together

14:47

to connect every aspect of your

14:49

business. Because when you're made to work

14:51

this hard, you need a seamless network

14:53

made to work even harder. Spectrum

14:56

Business, made to work. Learn more

14:58

at spectrum.com slash work.

15:01

Hi, my name is Jesus Rubalcaba. I'm the owner

15:03

of Paper Tacos Greeting Cards. And

15:05

my favorite episode of How I Build This is

15:08

May of Chesapeake Bay Candles.

15:10

I could really relate to her, especially when

15:12

she talks about going to trade shows and people just

15:14

passing her by. Trying to reach out

15:17

to buyers of several department

15:19

stores and hoping to get an order. Scaling,

15:22

trying to create manufacturing. And

15:24

all the struggles that she faced there are things

15:26

that I'm currently trying to overcome.

15:29

So I really resonate with her story and

15:31

really appreciate that you all shared it with us.

15:33

If you wanna share your favorite episode

15:35

of How I Built This, record a short

15:37

voice memo on your phone telling us

15:39

your name, where you're from, what your favorite

15:41

episode is, and why. A lot

15:44

like the voice memo you just heard. And email

15:46

it to us at hibt

15:48

at id.wondery.com. And

15:51

we'll share your favorites right here in the

15:53

ad breaks in future episodes. And thanks

15:55

so much. We love you guys, you're the best.

15:58

And now,

15:59

back to the show.

16:07

Welcome back to How I Built This Lab. I'm Guy

16:09

Roz. My guest today is Cody Finke,

16:11

co-founder and CEO of Brimstone.

16:13

This company has found a way to produce

16:15

cement that eliminates carbon

16:17

emissions, which could have a big impact

16:20

on our climate. But back

16:22

in the late 2010s, Cody had

16:24

just started exploring the idea at Caltech.

16:28

We looked around at the existing solutions

16:30

and we saw that most folks were working

16:32

on making a novel material,

16:35

not Portland cement, which makes a lot of sense

16:37

because if you make a novel material, then

16:39

you don't have to use limestone and

16:41

therefore you don't have to make the CO2. And

16:44

Portland cement, we should mention, is like the most

16:46

common type of cement used around

16:48

the world. It's probably in your home or

16:51

on your sidewalk. It's basically just the

16:53

term for cement. It's

16:55

not from Portland, Oregon or Portland, England.

16:57

That's what it's called. That's right. All

17:00

right. So you initially thought, okay, let's just take

17:03

the same materials, the limestone. I think it's

17:05

like aluminum and there are a few other components that

17:07

go into making cement. Let's

17:10

use these components, but just change the

17:12

chemistry and see

17:14

what happens.

17:15

Yeah. Or maybe even use some

17:18

different components. Maybe we could just make a different

17:20

material that still works like

17:22

Portland cement, but is not Portland cement. And

17:25

one of my early mentors was one of

17:27

the women at Caltech who was leading the entrepreneurship

17:30

program. Her name is Stephanie Anchinski.

17:32

And she was like, well, you should go talk to customers.

17:36

And we learned that it'd be very hard to

17:38

enter the market with a novel cement. And when you say

17:40

a novel cement, a cement that was not Portland

17:42

cement. That's right. Yeah. And

17:45

the reason for that was basically it's just

17:47

risk. If you're a structural engineer or

17:49

a builder or a concrete provider, then

17:52

you want your material insured in case

17:55

there's a problem with it. And you also

17:57

don't want construction delays. You want

17:59

to make sure that every everyone who's building the building knows

18:01

how to work with the material because both

18:03

structural failures and construction delays are way

18:06

more expensive than the cement. They're like 10 to 100 times

18:08

more expensive. And because

18:11

of those things, we basically found that

18:14

no one that we talked to was excited about using

18:16

a novel material. It seemed just too

18:18

structurally hard. And that was actually the

18:20

big aha moment, which really simplified

18:23

the problem. We realized that, okay, if

18:25

we want rapid adoption, which is

18:27

important for climate, but we want to solve the problem

18:30

quickly, then you need

18:32

to produce ordinary Portland cement.

18:35

Yeah. So we said, okay, great.

18:37

Where's all the calcium in the world? And

18:40

we found that the calcium was in three places. There's

18:43

limestone, which cement is made out of today.

18:46

There's gypsum, which cement has been made out

18:48

of in the past.

18:50

And then there's calcium silicate, which

18:52

no one had ever made from that data. Huh. And

18:54

from what I understand, these calcium silicate

18:57

rocks are abundant, right? Like I think

18:59

you're talking about rocks made

19:01

out of silicate materials that also have calcium

19:04

in them. So I guess like basalt

19:06

would be an example. Yeah. Well,

19:09

but I mean, presumably there's

19:11

a reason why limestone

19:14

is still used. I mean, I know

19:16

that maybe an answer could be well, it's just been

19:18

tradition or it's just what people are used to, but

19:21

there must be some

19:23

reason. Is it stronger? Is it cheaper

19:25

to get to? Like why, if these

19:28

other natural resources exist

19:31

that have the necessary components to

19:33

make cement, why weren't they used in the past?

19:36

Yeah. The thing that we have to realize is that

19:39

the production of Portland cement has been

19:41

around for at least 150 years.

19:44

Right.

19:44

And the reality is, is the production of commodity

19:47

chemicals, the like production method tends

19:50

to change every 50 or a hundred years. You

19:52

know, it takes a long time. The global economy really

19:54

has to change in order to make a new

19:56

system more economical. Right. So for over a year, we've

19:59

been able to do that.

19:59

century, limestone was the most economical

20:02

way to make cement. But there's

20:04

been some massive structural changes in the economy

20:07

that have made a pretty recent phenomena

20:10

that we no longer think limestone is the most economical

20:12

way to make cement. The current production

20:15

of cement deck super lies on the production

20:17

of electricity and steel from coal. And

20:20

both of those industries' growth have slowed and

20:23

that is leading to a domino effect where the price

20:25

of cement has been rising. So why

20:28

was cement made from limestone? Because it's the cheapest way,

20:31

or it was. The economy has now changed

20:33

over the last 150 years and we

20:35

believe that it's no longer the cheapest way. So

20:38

is it more expensive to make it from

20:40

calcium silicate? In the modern economy,

20:43

we think that we'll be lower cost at scale. And

20:45

that's core to our philosophy because we don't think that

20:47

the technology will scale globally if it's not

20:50

lower cost. And if it doesn't scale globally, it

20:52

doesn't have a big impact. And if it doesn't have a big

20:54

impact, then I'm not interested.

20:55

So what about the strength of

20:58

the end product? I mean, is it

21:00

as good as Portland cement? So

21:02

it is Portland cement. It is. Yeah,

21:05

it is Portland cement. So that's the key

21:07

thing, right? We don't think global adoption will

21:09

happen if it's not Portland cement. Right.

21:12

Or at least won't happen quickly. All right. So you basically

21:15

say calcium silicate, which

21:17

is a type of rock that's abundant.

21:19

It's available around the world. It has all

21:22

basically the same essential properties as limestone

21:25

that make it a great material for making

21:27

Portland cement.

21:28

And essentially, it's not a carbon sink,

21:31

right? Carbon is not stored inside of

21:33

calcium silicate. That's right. So

21:35

calcium silicate rocks, they don't have any CO2 in them.

21:38

So how does your

21:41

process eliminate carbon emissions?

21:43

I mean, when the rocks are heated, I understand

21:45

they don't really that that's abundant. It's

21:48

available around the world. It has all

21:50

basically the same essential properties as limestone

21:53

that make it a great material for making

21:55

Portland cement. And essentially,

21:57

it's not a carbon sink, right? Carbon.

22:00

is not stored inside of calcium silicate.

22:02

That's right. So calcium silicate rocks, they

22:04

don't have any CO2 in them. So

22:07

how does your

22:09

process eliminate carbon emissions?

22:11

I mean, when the rocks are heated, I understand

22:13

they don't release carbon like limestone,

22:17

but there still are emissions in the process, right?

22:20

So there could be emissions in the process

22:22

if you use a dirty fuel for

22:24

producing the heat, right? They can be produced via

22:27

clean electricity or a fossil

22:29

fuel or anything else. But

22:31

the beauty of our process is that actually it can be

22:34

substantially lower carbon or even carbon negative under

22:36

a wide range of energy sources, including

22:38

the use of those dirtier fuels. And

22:41

the reason that is, is because the calcium

22:43

silicate rock, A, does not contain any

22:45

CO2. So we eliminate 60% of the emissions

22:47

just by using a different rock. And then

22:50

B, it produces a magnesium-based

22:53

waste product.

22:54

And that magnesium-based waste product will passively

22:56

sequester CO2, just sitting on the ground.

22:59

It will react with CO2 in the air to permanently sequester

23:01

CO2. So

23:04

essentially what you're saying is when you make the cement,

23:06

the byproducts of it actually sequesters

23:09

carbon in this magnesium

23:11

byproduct, which you can then do what with you? Bury

23:14

it underground? What do you do with it? Yes, there's a lot

23:16

of things you could do with it. Basically, the simplest thing to do

23:19

with it is just put it in our tailings pile and then backfill

23:21

our quarry with it at end of life. So when

23:23

you've got an empty quarry, oftentimes

23:26

it gets filled up with water, right? But

23:28

you just fill it up with this material. And

23:31

there's no risk of it leaching

23:33

or anything. It's just basically a carbon store. That's

23:36

right. This is a normal rock.

23:38

Essentially, if you can do this at scale, what

23:40

you're saying is not only can you eliminate

23:43

carbon emissions from the production

23:46

of cement, but you can actually

23:48

remove

23:49

carbon from the atmosphere by sequestering

23:52

it in this byproduct that comes out

23:54

of the process, this magnesium.

23:56

That's right. And magnesium

23:59

carbonate is baby powder.

25:26

Bioni

26:00

BioFire has created the world's first handgun

26:02

with an electronic firing system that unlocks

26:05

instantaneously upon fingerprint

26:08

or facial verification. And then,

26:10

most importantly, relocks once

26:12

the user lets go of it. The idea

26:14

is by no means new, so in this episode

26:16

I spoke with Kai about what makes his technology

26:19

so groundbreaking and a little

26:21

bit about the evolving U.S. gun market. You

26:24

can find this episode by following how I built this

26:26

in your podcast app and scrolling

26:28

back a little bit to the episode of Biometric

26:30

Smart Gun with Kai Klopfer of BioFire,

26:33

or by searching how I built this BioFire,

26:35

that's B-I-O-F-I-R-E, wherever

26:39

you listen to podcasts.

26:43

Welcome

26:46

back to How I Built This Lab. I'm Guy Raj.

26:48

Here's more for my conversation with Cody Finke, co-founder

26:51

and CEO of Brimstone. They've

26:54

developed a carbon negative process for

26:56

manufacturing cement, which could have a

26:58

massive impact in reducing carbon emissions

27:01

around the world. I know you've started

27:03

to raise a lot of money. You've raised over $60 million.

27:06

Tell me how far along

27:08

you are in proving that this

27:10

works. Yeah, so just

27:13

this last July, we got a third-party certification

27:15

that we, the cement that we made passed

27:19

the existing standard for an air-prote. And cement showing

27:21

that it's chemically and physically identical to

27:23

the convention produced product. So we

27:25

have now developed a process that

27:27

is the third ever process to make ordinary-prote

27:30

and cement. And now we're working on

27:32

scaling up to a pilot scale version

27:35

of that process that is optimized such that we are confident

27:38

it will be lower cost at scale.

27:40

So right now, I think you're based in Oakland.

27:43

And I think you might have another facility in Idaho.

27:46

So I guess in terms of your business

27:49

model, because obviously you have a mission but you're

27:51

also a business with investors. I

27:53

mean, I know, for example, here in California

27:55

where I live and where you're based, I think

27:58

by maybe by 20... 35, I

28:01

think.

28:02

The cement sector in California has

28:04

to achieve emissions 40%

28:06

below baseline levels,

28:09

right? That's right. So that's significant.

28:12

And then by 2045, it's been net zero. That's

28:15

right. So that's good for a business like yours

28:17

because developers in California will have to use

28:19

your products. But that being said, what's

28:22

to prevent

28:23

C-MEX, which is a Mexican multinational

28:25

or Alamo, which is a big US-based

28:28

company, or Cal Portland,

28:30

another US-based cement company

28:32

from just doing the same

28:34

thing. Is your process

28:36

so hard to replicate or is it patented

28:39

or what? Yeah. So the process

28:41

is patented and the utilization of this rock

28:44

to produce Portland cement is also patented.

28:46

So

28:47

another company would need to license

28:49

or joint venture with us in order to make

28:51

cement via this process. Wow.

28:54

So essentially what you're saying is unless they can

28:56

come up with a different method,

28:57

this is going to be the standard way to make Portland

29:00

cement, at least in places like California and

29:02

other countries with stricter laws

29:04

in

29:05

the next 10 to 20 years.

29:07

That's right. And there are

29:09

no other major sources of calcium

29:12

besides these silicate rocks. So the other two are

29:14

limestone and gypsum. Those produce CO2

29:16

or sulfuric acid as byproducts. So

29:19

this is the beauty of our product.

29:20

So tell me about conversations you

29:22

were having, if at all, with some of these

29:25

big legacy cement manufacturers, these massive

29:28

companies that

29:29

produce cement. Yeah. So we

29:31

are trying to understand

29:34

the right way to work with these companies. We've had

29:36

many, many conversations with them.

29:39

And basically we

29:41

decided that the right time to work

29:43

together is when we have a process

29:45

working at scale. If we were to work together

29:48

earlier, then we would potentially jeopardize

29:50

our intellectual property, which is the

29:53

only thing that basically how brimstone

29:55

maintains its investibility is by keeping its

29:57

intellectual property secure. Once

30:00

we have the process at scale and we're at cost

30:02

parity or better, then we're basically

30:04

eager to join venture or license to

30:07

these existing cement companies so that we can

30:09

get the process out into the world as fast as possible

30:11

and decarbonize cement

30:13

as much as possible and as fast as possible.

30:16

So, sort of walk me through the next five

30:18

years. I mean, presumably, it's going to

30:20

be a while before you guys are

30:23

bringing in revenue. That's

30:25

right.

30:27

Yeah. So, within the next five years, what we'll be working on is

30:29

scaling up the process. The

30:31

next step is building a pilot plant.

30:33

In that pilot plant, we're being very careful to

30:35

build it so

30:37

it actually represents a plant that would be lower

30:39

cost at scale. Then from there, we

30:41

will work on building our first commercial plant. A

30:45

commercial cement plant that's been built 3,000 times

30:48

before takes two or three years to build. So,

30:50

in the next five years, we will be working on building

30:52

a first commercial plant. I think it's probably unlikely that it's

30:55

fully operational. Within five years.

30:58

Yeah. Who do you think your initial

31:00

customers will be? A lot

31:02

of these huge construction companies

31:05

probably have massive contracts with massive

31:08

cement manufacturers. So, what do you

31:10

think your approach is going to be?

31:11

So, it's a pretty complex market

31:14

where

31:15

normally a real estate developer will

31:17

put out a request for proposal for a building and

31:19

then someone will answer that request for proposal, typically

31:21

an architecture firm or an engineering firm or both. They

31:25

will designate a builder or a general contractor and

31:27

the general contractor will then buy concrete

31:29

from a concrete company. In order to make the concrete,

31:32

that concrete company buys cement from a cement company.

31:35

Usually, the cement company and concrete company

31:37

are the same parent company. The

31:39

only companies that ever buy cement are concrete

31:41

companies which are typically owned by cement

31:44

companies. But the folks that ultimately pay for

31:46

it are like two or three steps down

31:48

the value chain. They're the real estate developers. We

31:51

see as our early customers, real estate developers

31:53

that are highly motivated to decarbonize

31:56

because the first plants the cement is quite

31:59

likely

31:59

to be.

31:59

piece than kind of superuse cement.

32:02

So you need some environmental motivation. Later,

32:06

once we're at scale and essentially joint

32:08

venturing with existing

32:10

companies or build their own plants or licensing

32:13

and we're not more expensive, right, we're cost-parateer

32:15

better, then the solution is obvious.

32:17

It's

32:18

does a company want to buy something that's the

32:20

same cost or lower that is also better

32:22

for the environment? The answer is it's obviously yes.

32:25

It seems like a no-brainer, right, that

32:27

if 8% of carbon emissions come

32:29

from cement and the technology

32:31

is there to do it and to do it cheaply,

32:33

the challenge now

32:36

is that existing cement factories are essentially

32:38

at limestone quarries. So there

32:41

is a cost associated with transforming

32:44

the system. It's going to take a lot of

32:46

money and time to do it. That's right. It's

32:48

just like it's taking money and time

32:50

to transform a coal and

32:52

natural gas based electricity generation system

32:54

into

32:55

a renewable one. It'll be the same

32:57

for the cement industry. I don't think there's a

32:59

silver bullet in anything, right? There's

33:01

going to be some cost to doing that and

33:03

that's going to create some delays unfortunately,

33:06

unless there's

33:08

massive regulation at the global scale, which

33:10

I think also is hard to imagine.

33:12

Just put your business head on again for a moment.

33:15

To do this at scale, you're going to have to raise a lot

33:17

more money presumably. That's right. I

33:20

mean hundreds of millions of dollars over time.

33:22

So we want to see Brimstone's technology

33:24

deployed to produce the world's cement.

33:28

So let's

33:28

say a cement plant, a modern cement plant

33:31

costs around a billion dollars

33:32

and there

33:34

are 3,000 of them today and there

33:36

probably will be 5,000 by

33:38

the end of the century because we will need to

33:40

develop the rapidly developing world as

33:43

well as transition to

33:45

making new ways to make energy and everything else

33:48

that's required for the green transition, which all of that takes

33:50

cement. So at a billion dollars

33:52

per plant and 5,000 plants, that's ultimately

33:55

5 trillion dollars.

33:59

quite a bit, but it fundamentally

34:02

will make money. So that's a attractive

34:04

investment solution. So once we can demonstrate

34:06

the technology works and get down

34:08

the cost curve by getting to scale, I don't

34:11

think that financing will be an issue. I think

34:13

that the challenging part is

34:16

raising money for the early plants. But

34:18

luckily, we live in a world

34:21

where there are lots of people that are thinking

34:23

about those problems. And so I think

34:26

that the future is actually quite bright.

34:28

Awesome. Cody, thank you so much. Yeah,

34:31

thanks, Guy. That's Cody

34:33

Finke, co-founder and CEO

34:35

of Brimstone. Hey, thanks

34:38

so much for listening to the show this week. Please

34:40

make sure to click the follow button on your podcast

34:42

app so you never miss a new episode

34:45

of the show. As always, it's free.

34:47

This episode was produced by Alex Chung with

34:49

editing by John Isabella and research help

34:51

from J.C. Howard. Our music was

34:54

composed by Ramtin Aralui. Our

34:56

audio engineer was Patrick Murray. Our

34:59

production team at How I Built This includes Carla

35:01

Estevez, Casey Herman, Chris Messini,

35:04

Elaine Coates, Malia Agadello, Neva

35:06

Grant,

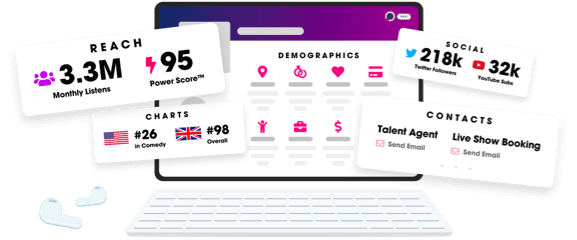

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us