Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:21

Hello, friends. And welcome to a new episode

0:24

of Making Coffee. This is episode 68.

0:26

As I record this, it is December. Nick

0:29

and I are preparing to host the next cohort of FTCs

0:31

and begin a new harvest, which is wild

0:34

because a coffee from the last harvest has only

0:36

just arrived in the United States. Shipping

0:38

from Guatemala to the United States shouldn't normally

0:40

take this long, but there were some unexpected

0:43

shipping delays, so it's taken almost a year

0:45

for this coffee to get to its destination. The

0:48

green coffee will be available for purchase

0:50

from Yellow Rooster Coffee Imports out of Tampa,

0:52

Florida. I'll share more information

0:54

in the coming days on availability and

0:56

quantities. You know,

0:58

I often get asked why I chose to

1:00

leave the wine industry and hop over to coffee.

1:03

There are many reasons, but one important

1:05

one was that at the time coffee came calling,

1:08

I was working for a very expensive winery,

1:10

a very exclusive winery. And

1:13

exclusivity has always made me feel a

1:15

little uneasy. I like

1:17

making things, and people love wine,

1:19

but due to the price point, not too many people

1:22

could taste the wine that I helped make. During

1:25

my time at Opus One, a single bottle

1:27

was 250. Today,

1:30

a single bottle is 525

1:33

Perhaps even fewer people are able to taste

1:35

this wine today compared to 10 years ago.

1:38

There are a lot of wine drinkers in the world, but

1:40

one allure of the coffee industry was that

1:42

there are so many more coffee drinkers.

1:45

I thought that if I made the move to coffee, I

1:48

felt like I would have more in common with more

1:50

people. And making

1:52

coffee, processing coffee, is one of my

1:54

favorite ways to spend my time. But

1:56

it doesn't feel fully satisfying unless

1:58

other people get to taste it. So

2:01

all that to say, I am eagerly awaiting when

2:03

I can share when this coffee from Guatemala will

2:05

be available, and in a few months

2:07

I will also have some coffee from the previous

2:09

FTC in Kenya available in the

2:11

U. S. So if you're in the United

2:13

States and would like to buy green coffee

2:16

or roasted coffee, please sign up to my newsletter,

2:18

which is where I will announce coffee sales

2:20

and all that information on how to get samples.

2:24

And I'm directing you to my email newsletter because

2:27

this podcast is not on a regular schedule,

2:29

and this will be especially true for the next few

2:31

months. Like I said, we're hosting two

2:34

fermentation camps. I have a

2:36

private consulting client that I'm going

2:38

to go visit, so I'll be traveling for that. We

2:41

are starting a new coffee harvest, uh, let's

2:43

not forget Christmas and the end of the year

2:45

holidays. And then, of course, during

2:47

harvest time is when we have a lot of visitors. So

2:49

all of those things contribute to keeping

2:51

me from making new episodes. However,

2:54

I do want to say that even though the podcast is taking

2:57

a break during this busy harvest time, I'm

2:59

still regularly doing office hours for

3:01

our community. So office hours definitely

3:04

don't take a break. And

3:06

office hours are, I don't know, it's been, it's

3:08

been a really fun, surprising

3:11

evolution of the podcast because it's

3:13

like a live podcast, but with listener

3:15

participation. So I'm not just

3:18

speaking to myself into a void. And

3:20

in fact, today's episode was first workshopped

3:23

during a recent session of office hours.

3:26

and the newsletter is also where I announce

3:28

future office hour dates, and then where

3:30

I send the replay in case you missed the live

3:32

session. Alright, that's

3:34

enough introduction. What are we talking about

3:37

today? Well, you clicked on

3:39

this title because it's about fermentation

3:41

versus germination, and yes, that

3:43

is the subject matter, but the over

3:45

story is about the evolution of coffee

3:48

appreciation. And I

3:50

hope to inspire coffee appreciation in

3:52

you through a historically ignored medium,

3:55

coffee drying. I have been

3:57

trying to make this episode for years, but

3:59

I couldn't figure out how to make it come together.

4:01

Coffee drying is tremendously important to

4:03

quality, but it's often overlooked

4:06

because it's Well, dry.

4:09

Which is a synonym for boring. Well

4:12

friends, this is not to be a dry

4:14

episode about drying. So if

4:16

you're skeptical that copy drying can be fascinating,

4:19

please hold your judgment and stick around. But

4:22

before we talk about the final stage of processing,

4:25

We must first review how we got into this perspective.

4:29

Why have we ignored coffee drying for

4:31

basically the entire history of specialty

4:33

coffee? Most

4:36

of you who hang out in this corner of the internet will

4:38

agree that specialty coffee is a young industry.

4:41

Most of you will also agree that quality

4:43

has not been the principal driving factor

4:46

in coffee prices. Coffee

4:48

was mostly about caffeine, the functional

4:50

effects, not the pleasure of flavors.

4:53

And when coffee drinkers did begin to care about

4:55

taste and quality, the first place

4:57

they looked to was the roasting. The

5:00

older history of coffee is that quality was

5:02

largely ascribed to roasting style.

5:05

Brands would use words like Italian roast,

5:07

French roast, or city roast as a quality

5:09

differentiator. How the seeds

5:12

were roasted mattered more than where the seeds

5:14

were grown or even the genetics of the coffee.

5:17

You could buy green coffee from anywhere,

5:19

at whatever price, because it's not what

5:21

made the coffee special. The

5:23

thinking was that how you apply heat to transform

5:26

the green coffee is what made it taste different.

5:29

This attitude created the anonymity

5:31

and interchangeability of commodity coffee

5:34

that this new brand of specialty coffee seeks

5:36

to rectify. We now know

5:38

that roasting of course matters to flavor

5:40

and quality, but also where

5:43

the coffee seeds are grown and the variety

5:45

also matters to quality. All of these things

5:47

come together. And if you

5:50

listen to this podcast, we might take

5:52

for granted that coffee from different countries

5:54

tastes different. Different. Of

5:56

course Kenyan coffee tastes different from Sumatran

5:59

coffee. Of course Brazil tastes different

6:01

from coffee grown in Ethiopia. It's

6:03

easy to forget that for so much of its history,

6:06

coffee was just coffee, a

6:08

single aroma note. Many

6:11

years ago, I was listening to an interview with

6:13

a popular fiction author. I

6:15

don't remember much about the interview except for

6:17

a part where the author was describing his

6:19

love of chocolate. His new

6:21

book had nothing to do with chocolate, but the

6:23

author mentioned it as a new hobby of his. He

6:26

was talking about his favorite chocolate origins,

6:29

how he could taste the difference between chocolate from

6:31

Nicaragua and chocolate from Ghana. It

6:34

wasn't a brag, just a fact. But

6:36

the interviewer was stunned. He

6:38

treated this information of tasting a chocolate

6:40

bar and guessing the country of origin as

6:43

if this author was getting information directly

6:45

by communicating with spirits. So

6:48

like, you just taste it and

6:50

you know where it's from? He asked. This

6:53

was about 15 years ago, and I have to admit

6:55

that at the time, I identified more

6:57

with the interviewer. I too thought

6:59

it was really special. Wait,

7:02

you can taste something and just tell

7:04

me where it's from? The interviewer

7:06

and I both felt like we had witnessed a magic

7:08

trick. Which reminds me

7:10

of the following quote by science fiction author

7:13

Arthur C. Clarke. Which

7:15

is, any sufficiently advanced technology

7:17

is indistinguishable from magic. Shortly

7:21

after hearing that interview, I started sensory

7:23

training in my previous life as an analogist

7:25

in Napa Valley, and I learned not

7:28

only to identify chemically synthesized

7:30

compounds like vanillin from the

7:32

natural aromas like vanilla, but

7:34

also to identify the origin. I

7:37

trained my nose to identify Mexican vanilla,

7:40

Tahitian vanilla, or vanilla grown

7:42

in Madagascar. And

7:44

well, that's it. That type of practice turned

7:46

what originally felt like magic into something

7:49

quite ordinary. I

7:51

lost some of that magic. So much so

7:53

that it's hard for me to remember what my experience

7:55

of coffee was before I started working in

7:57

coffee. I feel too

7:59

close to it. It's like trying to remember

8:01

my life before my siblings were born. I

8:04

am the oldest. I've lived many years

8:06

before they existed, but now

8:09

I can't remember that time. I only

8:11

remember my life with them in it. I

8:14

came to coffee later in life, later than

8:16

most people, and yet it's hard for me

8:18

to remember my experience of coffee in

8:20

the before times. And while that's

8:22

true for coffee, Even today, all

8:24

these years later, I can clearly remember

8:27

the feeling of being amazed that someone

8:29

could identify the origin of cacao

8:31

from tasting a chocolate bar. And

8:34

this is particularly embarrassing to admit,

8:36

because at that point I was already familiar

8:39

with connecting how Sauvignon Blanc grapes

8:41

grown in New Zealand or California or France

8:44

were completely different. Grapes

8:46

felt familiar, but somehow cacao

8:48

still managed to invoke a sense of awe in

8:50

me. I took grapes for

8:52

granted then. I take coffee for granted

8:55

now. But somehow, cacao has

8:57

managed to escape this fate. Do

8:59

you take for granted that coffees from different countries

9:02

taste differently? Do you know that

9:04

there are many people for whom that geographical

9:06

identification is still a mystery,

9:08

and can still be considered in the realm

9:11

of magic? Whether or not

9:13

it feels like magic to you or is old hat,

9:16

we can agree that more consumers are learning

9:18

to value and identify the noticeable

9:20

flavor differences associated with

9:22

different countries. So

9:24

besides roasting profile, another

9:26

early challenge for appreciating coffee flavor

9:29

was a country where the seeds were grown. In

9:32

our appreciation of coffee, we have graduated

9:34

from valuing roasting to noticing

9:36

origin, and today we find ourselves

9:39

in a place where a podcast like this one can

9:41

exist because we know the importance of

9:43

processing. That's

9:45

what we talk about the most together. The fermentation

9:48

and the microbes of coffee. Processing

9:51

can be a powerful way to add value and

9:53

complexity to coffee, and I have advocated

9:55

for using microbes as a way for producers

9:57

to have more flexibility in their offerings.

10:01

For example, most of you listening will have

10:03

a flavor connection to dry process or

10:05

natural coffee. Something like

10:07

a heavier body and more fruit forward.

10:11

And perhaps you also have a flavor connection to

10:13

washed coffees as being brighter

10:15

and maybe cleaner tasting, higher acid.

10:19

Very clearly, these two methods produce

10:21

different tasting coffees. And

10:23

once people learn which profile they like, they

10:25

tend to seek one out and maybe stay

10:27

away from the other. However, these coffees

10:29

are not just different in flavor. More

10:32

importantly, the amount of labor,

10:34

effort, infrastructure, climate, and

10:36

general resources it takes to produce these

10:38

methods are also very different.

10:41

And the skills to know when you've made

10:43

a good version of that are completely different

10:46

skills. This

10:48

is why I care about this topic. Not

10:50

because of the flavor, but because of the effort.

10:53

Most producers still believe that the only way

10:55

to get a flavor of a washed coffee, meaning

10:58

a clean and bright cup, is

11:00

to do the washed method. And conversely,

11:03

the way to get a heavy bodied and fruit forward

11:05

profile is to make a natural. Most

11:09

coffee buyers think that these methods are

11:11

interchangeable, so they frequently ask

11:13

producers to make one or the other, as

11:15

if they are arriving in a bakery and are choosing

11:17

between a cake and a muffin. But

11:20

these methods are so different and require different

11:23

skills and climates that it would be like going

11:25

to a bakery that specializes in desserts

11:27

and asking for a burger. For

11:30

many small coffee producers, they have

11:32

been processing coffee one way, either

11:35

washed or natural. It's very

11:37

rare that historically they produced both,

11:40

had the equipment for both, and did both

11:42

styles well. So usually

11:44

asking them to make the switch is not as easy

11:46

as swapping some ingredients. And

11:48

even though it's not easy, many producers

11:51

still do it want to differentiate

11:53

their coffee. They want to reach new markets.

11:56

They build a new facility, they buy stainless

11:58

steel bioreactors, or build a hundred

12:01

new raised beds. They buy new equipment

12:03

and construct washing channels. They

12:05

approach it by changing the external environment,

12:08

the infrastructure, the equipment. I'm

12:11

not saying this doesn't work, of course it does, but

12:13

I do believe for many there is an easier way.

12:17

One central thesis to my work with coffee producers

12:20

is that changing processing protocols is

12:22

not the only way to get a new flavor profile.

12:25

Instead of changing the whole environment and

12:28

equipment, often we can just swap

12:30

microbes to achieve a similar result.

12:33

This matters because most Central American

12:35

coffee producers have traditionally produced

12:38

coffee in a washed manner. The

12:40

wet mills are built to be efficient in this

12:42

system. But now that natural

12:44

and fruity coffees are popular, the advice

12:46

is to change the style of processing to meet

12:49

the consumer trends. This

12:51

is challenging for many producers because our

12:53

Central American climates are more humid

12:55

than areas in Africa where the natural process

12:57

is traditionally used. Central

13:00

America also has a general lack of labor

13:02

that I haven't seen during my work in Africa.

13:05

When producers in humid climates, used

13:08

to making washed coffees, are asked to make naturals,

13:11

many face mold issues and see their quality

13:13

decrease instead of increase. The

13:16

coffees don't behave the same way because

13:18

the climate is not adequate for that type of

13:20

processing. This leaves

13:22

coffee producers with the option of risking

13:24

the quality of their coffee to potentially

13:26

reach a new market, or maybe

13:29

not participating at all. But

13:31

there is a third option. Instead

13:33

of changing the infrastructure of processing, instead

13:36

of ditching your fermentation tanks and washing

13:38

channels for endless raised African beds,

13:41

I propose to use your wash method

13:43

and change the microbes. I propose

13:46

to keep using the wash method and change

13:48

the microbes to get closer to the flavor

13:50

profile of a natural. By

13:52

swapping microbes, we can make wash coffees

13:55

that taste more like naturals, or conversely,

13:58

natural processed coffees that taste more

14:00

like washed. This efficiency

14:03

has been interpreted by some as trickery.

14:05

This leads us to a tension we have in specialty

14:08

coffee about process forward coffees.

14:12

the term process forward to encompass

14:14

a style of processing where the country of

14:16

origin or the genetics of the variety are

14:18

secondary characters in the flavor story.

14:22

An example would be anything that can be described

14:24

as funky. When

14:26

you get more funky flavor than genetic

14:28

expression, That's a process forward

14:31

coffee. If any of the flavor

14:33

notes include the words whiny, alcoholic,

14:36

boozy, or whiskey, this is

14:38

a process forward style. But

14:41

I think this could also refer to something like

14:43

a geisha processed by carbonic

14:46

maceration. The carbonic maceration is

14:48

a method that imparts a strong character

14:50

that can often overpower the delicate

14:53

genetics of a geisha. In

14:55

fact, one criticism I've heard of so

14:57

called anaerobic coffees is that they

14:59

are starting to taste the same. An

15:02

anaerobic Bourbon from El Salvador is

15:04

often indistinguishable from an

15:06

anaerobic Castillo from Colombia. The

15:09

process that was supposed to pluck these coffees

15:11

from obscurity by creating differentiated

15:13

flavors is the very thing that is dragging

15:16

them back into interchangeability.

15:19

Process forward coffees were supposed to be the

15:21

answer to give producers a visible role

15:23

and to differentiate them from commodity

15:26

coffee. And yet, we find ourselves

15:28

in a very similar place where we started.

15:31

Which is, Buyer's looking for trendy buzzwords

15:33

to put on a label instead of an identity.

15:36

So there is a tension here with processing. There's

15:39

a strong reaction against process

15:41

forward coffees. And I believe

15:43

at the heart of the matter is the question of authenticity

15:46

of flavor. No one

15:48

wants to feel like they have been tricked. And

15:50

if we can use processing to make one thing

15:52

taste like another, isn't this trickery?

15:56

How would one even do this? Let

15:59

me introduce you to my friend and FTC alum,

16:01

Julie. Julie manages a

16:03

1. 5 acre diversified agroforestry

16:06

coffee orchard in Oahu, Hawaii.

16:09

Julie's personal preference is washed coffees,

16:12

but 1. 5 acres is not big

16:14

enough to build a wet mill facility. And

16:17

even if Julie had infinite funds to build

16:19

a wet mill, I doubt that she would, because

16:21

we all know how water intensive the washing

16:23

process is. A traditional

16:25

wet mill can use up to 3,

16:28

000 liters of water to produce a single bag

16:30

of green coffee. And, uh, In

16:32

this case, I'm talking about the really big operations

16:34

that produce several containers of coffee per year.

16:37

A small holder using manual equipment

16:39

uses much less water, like 400

16:41

liters for one bag of green coffee. But

16:44

if you do a natural process and manually

16:46

sort instead of floating your cherries, you could easily

16:49

use zero water, which means

16:51

zero waste water, zero pollution, and

16:54

it's a much more environmentally friendly

16:56

process. way of processing coffee. Julie

16:59

has a Bachelor's of Science in Tropical Agriculture

17:02

and Environment, with a concentration

17:04

in Environmental Soil Science from the University

17:06

of Hawaii and a Master's in Science in

17:08

Tropical Plants and Soil Science from the University

17:10

of Hawaii, specializing in agrovoltaic

17:13

systems. Julie prefers

17:15

a flavor of a washed coffee, something with

17:17

higher acidity, brightness, and clarity,

17:20

but she can't justify the wash process

17:22

both financially, but also philosophically.

17:25

So Julie turns to microbes. She

17:28

can use very minimal water to process her cherries

17:30

with added microbes to approximate

17:32

the flavors of a washed coffee. This

17:35

leads to significant water savings, equipment

17:37

savings, and a natural

17:39

that tastes more like a washed coffee. Efficiency

17:43

or trickery? For me,

17:45

this falls squarely in the category of

17:47

efficiency, of, using

17:50

your resources well. Anything that would consider

17:52

this type of processing trickery, for

17:54

me, really misses the point. It

17:56

really misses the larger possibilities. We

17:58

have come a long way in our appreciation of

18:00

fermentation. So much so that

18:02

many of us may have forgotten that the word fermentation

18:05

actually used to be a negative word in coffee,

18:08

because it signaled a defect. And

18:10

even today, many can still use the word fermento

18:13

to describe something that has gone wrong, an

18:16

overactivity of microbes, of higher

18:18

acid production, basically putrefaction.

18:21

And for many, the word fermentation

18:23

is interchangeable with rot. or

18:25

rotting. Because

18:27

fermentation is a process by which microbes

18:30

found naturally on the skin of fruits remove

18:32

the mucilage for free and liberate the seed

18:34

to be able to dry it. The fermentation

18:37

step was seen as a high risk step.

18:39

The goal was to avoid defects. The

18:42

worst case scenario is that the fermentation

18:44

step ruined the coffee and gave it a defect

18:46

that made the coffee taste rotten or spoiled.

18:49

Conversely, the best a producer could

18:51

hope was to not ruin the coffee.

18:54

Those were the two options facing a producer

18:56

regarding fermentation. Either

18:58

ruining the coffee or preserving the assumed

19:01

quality of the fruit. Making the fermentation

19:03

be neutral or undetectable was the

19:06

goal of most producers, and continues to be the goal

19:08

of most producers in the commodity

19:10

space today. For much

19:12

of the history of coffee production, fermentation

19:14

has been seen as a necessary evil and

19:17

an unfortunate reality of coffee production.

19:20

This is one of the biggest cultural shocks I experienced

19:23

in 2014 when I started working with coffee,

19:25

because I could not disagree more with

19:27

this idea. The place

19:29

where fermentation takes place, the wet mill,

19:32

in Spanish is called a beneficio, translated

19:35

to a benefit. And yet the fermentation

19:37

was still demonized, and most producers wanted

19:39

me to help them shorten or eliminate the fermentation

19:42

altogether. My

19:44

work in the last 10 years has been to turn the beneficio

19:47

into a place where we can benefit the coffee,

19:49

where we can improve the coffee using the same

19:51

tool that most producers have avoided. I

19:54

think we're finally there. I feel very comfortably

19:57

there in, in that concept. We

19:59

are at a place where specialty coffee and fermentation

20:02

are friends and not enemies. Fermentation

20:04

is no longer seen as a necessary evil, but

20:07

an opportunity to add complexity, value,

20:10

and identity. And

20:12

why have we made it, I don't know, 20 minutes into

20:14

this episode when

20:16

I said that this episode is about drying

20:18

and not fermentation? Well, it's

20:20

because drying is still seen today like

20:23

we saw fermentation 15 years ago. Fermentation

20:26

was seen as a step that at worst ruined

20:28

coffee and at best did nothing,

20:30

was neutral. And I have noticed

20:32

that we believe the same of the drying phase.

20:35

We're treating it in a very similar way. We

20:37

were wrong then and we are wrong again. Most

20:41

producers I have worked with see the drying phase

20:43

as an inconvenience. It takes

20:45

the longest and therefore creates a bottleneck

20:47

for workflow. Everyone I know

20:49

is always trying to speed up drying and

20:51

shorten this phase of processing. And

20:53

it's in seeking speed that most of the damage

20:56

is done. I think the

20:58

seed is seen like wet laundry.

21:01

A wet item of clothing is pretty useless.

21:04

Only when it's dry do we recognize its value.

21:07

To get value out of the item, we just need

21:09

to get the water out. The essence

21:11

of the fabric and the function is the same.

21:14

But getting the water out is what makes the t shirt

21:16

useful. Similarly, a

21:18

wet coffee seed is not useful. Only

21:21

once dry can it be sold and roasted

21:23

and enjoyed. Drying is

21:25

seen as this annoying step, a barrier

21:28

to turning something unuseful into

21:30

something useful. It is this

21:32

reasoning that has lowered the potential

21:34

of so many good coffees. The

21:37

need for speed has led to a brutalizing

21:39

of coffee seeds. High temperature, high

21:41

air flow, no rest, racing

21:43

to dryness. And true. Most

21:46

specialty coffee knows that it's best

21:48

to lower peak temperatures and slow down a bit.

21:51

There is an emerging consciousness, a

21:53

movement towards gentle drying. But

21:56

this approach is still about reducing

21:58

risk, about damage control, we

22:00

know we can ruin coffee with bad drying.

22:03

And the best case scenario is preserving

22:05

inherent quality, being neutral,

22:07

with our drying so that we don't ruin the work

22:10

that Mother Nature did. Many still

22:12

think of drying like we used to think of fermentation.

22:14

We know we can really screw up our coffee if we

22:16

do it wrong, but we still don't see

22:18

how we can use it to make our coffee better.

22:21

And friends, how you dry the coffee

22:24

can absolutely make your coffee better.

22:27

A producer's choices are no longer to either

22:29

be neutral or ruin coffee. There's

22:31

always a third way. We can improve

22:34

coffee with the choices we make during drying.

22:37

How? Well, because drying is

22:39

not just a removal of water. Coffee

22:42

seeds are not like our t shirt. Fabric

22:44

plus water. Coffee seeds are

22:46

alive. And life plus water

22:49

equals change. While

22:51

the seed dries, it is not inert like clothing

22:53

drying in the sun. As the seed

22:55

dries, there are complex metabolic

22:57

reactions that occur and contribute to the coffee's

23:00

longevity and quality. It's

23:03

been challenging enough to get the industry to pay

23:05

attention to coffee processing and the role

23:07

microbes play, but drying might

23:09

be an even bigger challenge. One

23:12

of the biggest mistakes I see producers make

23:14

is investing in fermentation protocols, new

23:16

tanks, microbes, etc., and

23:19

then keep the same style of drying as they have

23:21

always used. Specialty

23:23

coffee needs specialty drying, and

23:25

the way that we have been drying coffee historically

23:28

is as limiting as when we thought the best

23:30

way to have high quality coffee was to

23:32

skip the fermentation. We

23:34

know that naturals and washed coffees have a different

23:37

flavor profile because we can taste the differences.

23:40

Those processing methods have different microbes

23:42

associated with them, and we know that microbes

23:45

through fermentation create acidity, mouthfeel,

23:47

and flavor compounds that can change the coffee.

23:50

A natural processed coffee, because it's in

23:53

a lower humidity environment, is

23:55

home to a certain species of yeast that are not

23:57

usually found on washed coffees. Yeast

24:00

break down the sugar in the fruit and create acidity,

24:02

mouthfeel, and flavor compounds unique to

24:04

natural coffees. But

24:06

all of this that I'm describing, all of this is

24:08

happening in the mucilage layer, outside

24:11

of the seed. And, what many

24:13

don't know, is that in addition to changes happening

24:15

on the outside of the seed, there are also internal

24:18

changes happening to the seed itself,

24:20

on the inside of the seed. So,

24:22

washed and natural coffees taste different

24:24

because of the microbes found on the outside,

24:27

And also what is happening to the

24:29

seed inside. And

24:31

how do we know that anything is even happening inside

24:34

the seed? How do we know that the coffee

24:36

continues to change over time? Because,

24:39

This is not what most people Many

24:42

believe that the peak of coffee expression

24:44

is found in a perfectly ripe cherry.

24:47

And this is the basis of terroir. That

24:50

what nature provides is perfection, and

24:52

our human activity is more likely to ruin

24:54

instead of improve upon nature. This

24:57

is the purist point of view of wanting

24:59

to harvest a coffee cherry at peak ripeness

25:02

and essentially freeze those attributes and

25:04

place that fruit in our cups. The

25:06

purist believes that good processing

25:09

should aim to get as close to this ideal

25:11

as possible. I

25:13

think this is what is meant by trying to make processing

25:15

transparent. The philosophy

25:17

is to make coffee processing as minimal

25:19

as possible. As non intrusive, as clear and transparent

25:22

as possible to be able to taste

25:24

nature's fruit. Long time listeners

25:26

know I have never liked this way of thinking, and I wrote

25:28

three episodes and made a YouTube video about

25:30

the fallacy and the pitfalls of terroir.

25:33

I haven't liked this way of thinking because of how it

25:36

neglects the human element and dismisses

25:38

the hard working microbes that provide flavor

25:40

and make coffee more complex. So

25:42

those of you who know how I feel will

25:45

know that I was also very excited

25:47

when I learned that one of my coffee heroes, Dr.

25:49

Flavio Borem, designed an experiment that

25:51

proves this theory, but from a different

25:53

angle. Borem is a

25:55

godfather of drawing and my secret mentor.

25:58

It's not a secret that I've kept from you guys, the listeners.

26:01

But he has no idea that he's been my secret mentor

26:03

for the last 10 years. His experiment

26:06

challenges the idea that the ripe coffee

26:08

cherry is really the highest expression of

26:10

flavor. Historically,

26:13

the idea of pressing pause on nature

26:15

to preserve the perfect fruit was not

26:17

possible. When I talk about

26:19

this topic in my presentations, I represent

26:21

this with a drawing of a coffee cherry trapped

26:23

inside of an ice cube so that it can be taken

26:26

from the farm directly to the cup

26:28

without the interference of pesky

26:30

machines or humans. It's

26:33

still not possible to do this on the farm, but

26:35

it is possible to do this in a laboratory

26:37

setting. And that's exactly what Dr.

26:40

Borrem did. A natural

26:42

coffee can take anywhere from three to four weeks

26:44

to dry down to 11 percent. Borrem's

26:46

experiment took coffee cherries at peak

26:49

ripeness and interrupted the drying process

26:51

at several points along the journey from

26:53

50 percent moisture down to 11. He

26:56

took a ripe cherry and eliminated the processing

26:59

and drying, essentially freezing the flavors

27:01

of the fruit in time. Then

27:04

he took another batch and let it go down to 30

27:06

percent moisture content before interrupting

27:08

the process. Then another batch went

27:10

longer, down to 20 percent before interrupting

27:12

the drying process. And another batch went

27:15

down to 18 percent before its process was

27:17

interrupted. And of course there was a final

27:19

batch where it was not interrupted at

27:21

all and it got to have its entire drying

27:23

journey as we traditionally see on

27:25

patios or raised beds all over the world.

27:29

By interrupting the drying process, he was able

27:31

to answer the question, when exactly

27:33

does a natural take on the flavor of a natural?

27:37

If a coffee cherry has an initial moisture

27:39

content of roughly 50%, and

27:41

we need to get it dry down to 11

27:43

percent to be stable, at which point

27:45

during its journey does it resemble the flavors

27:48

that we are familiar with? This

27:50

method of interruption is the equivalent of putting

27:53

raw batter in an oven and every few

27:55

minutes asking, are you a cake now? How

27:57

about now? Are you a cake now? When

27:59

exactly does the raw material resemble

28:02

the product that we consume? While

28:05

there is a case for the deliciousness of raw cake

28:07

batter, most of us agree that the raw

28:09

version is not the highest expression of quality.

28:12

But for some reason, we think of coffee this way.

28:15

We romanticize the raw coffee cherry

28:17

as the highest expression of quality and believe

28:19

our human work can only preserve or

28:22

ruin Mother Nature's effort. Have

28:24

you believed this? Have you believed that the ripe

28:27

coffee cherry is the highest expression of flavor?

28:29

Maybe you have, and you hadn't even considered

28:31

that you believed this to be true. That

28:33

any processing was essentially a lesser

28:36

version of what Mother Nature provided.

28:38

If you believe this to be true, then

28:40

when we analyze the coffee, you would

28:42

see that the least amount

28:44

of dry time, the closest

28:46

to the fresh cherry, would yield the highest

28:49

flavor concentration. You'd see

28:51

a peak, like we all imagined, as close to

28:53

harvest as possible, and then perhaps

28:55

a slow degradation, like a gentle

28:57

sloping curve going down and to the right.

29:00

Because if nature provides the maximum expression,

29:03

and all humans and processing do is

29:05

get in the way, then we should see the flavors

29:08

and complexity decreasing with time,

29:10

the way we imagine coffee fading with

29:12

age. The further you get away from

29:14

a ripe cherry, the lower the flavor

29:16

complexity should be, Because all

29:18

we're doing is ruining our coffee, right? All

29:21

we're doing with extra time and extra processing

29:23

is getting less of the good stuff, right?

29:27

What Perrin was able to show with chemical analysis

29:29

is actually the opposite. When

29:31

those coffees were chemically analyzed, the

29:34

one frozen at peak ripeness has the

29:36

least flavor expression. It was the least

29:38

recognizable in terms of flavor profile.

29:41

It's essentially the most boring coffee.

29:44

My words, not his. And

29:46

even the ones that had been allowed to go through the

29:48

partial drying process and down

29:50

to 30 percent or 20 percent or even

29:52

18 percent didn't have the

29:54

expected profile that we recognize and

29:56

value. The seeds had to go

29:58

through the entire drying process to

30:00

arrive at the flavor profile we associate

30:03

with a natural or dry process. Even

30:05

when science and tools of a laboratory allow

30:07

us to metaphorically press the pause button

30:10

on nature, The result is now what we

30:12

expected. Basically, you

30:14

have to bake the cake the whole way to get

30:16

it to taste like cake. To get it to

30:18

BE cake. The

30:20

drying process is adding value to

30:22

the final coffee. Not just because

30:24

it's removing water and making the coffee stable

30:26

for storage and shipping, but because

30:28

it's creating flavors and adding to

30:30

the complexity. I think this experimental

30:33

design is really brilliant because he

30:35

specifically didn't use a washed coffee. In

30:38

washed coffees, we see and smell and hear

30:40

the fermentation. We see bubbles, we

30:42

can measure temperature and pH changes.

30:45

Anyone who has seen a coffee fermentation

30:47

knows that the raw material is changing.

30:49

We can easily accept that washed coffees are

30:52

changing and improved by the fermentation. But

30:55

a dry process or a natural coffee go

30:57

from the tree to a raised butter patio. They

31:00

usually don't go into a tank or have any microbes

31:02

added to them. We think the actions

31:04

in the natural process are simply a removal

31:06

of water. But if this were true,

31:09

then the results would have shown that skipping the long

31:11

drying process would preserve nature's work

31:14

best. But what we see is

31:16

that a ripe cherry is not the peak of

31:18

flavor, and everything else is a slow,

31:20

steady decline towards staleness. As

31:22

if we are standing on a diving board and our only

31:24

option is to go down. So

31:26

instead of a peak, A ripe cherry

31:29

is the foundation, it is the baseline,

31:31

it is the bottom, and we can treat it like

31:33

a trampoline where we can joyfully bounce

31:35

upwards in search of bursts of flavor expression.

31:39

Now that I hope you're willing to see coffee drying in

31:41

a different light, we can start to talk about

31:43

the why and the how. If

31:46

fermentation is the outer transformation

31:48

of the mucilage, then what is happening

31:50

inside? This is where using

31:52

the term coffee beans limits our imagination.

31:55

Not beans, but seeds. And

31:57

what is the purpose of a seed? The purpose

32:00

is not to be consumed by us but to become

32:02

a new plant. When a seed germinates,

32:04

when it prepares to become a new plant, it

32:07

needs to undergo a complex cascade

32:09

of reactions. reactions

32:11

have consequences for shelf life and coffee

32:13

quality. And the ability

32:16

to germinate is a huge difference between washed

32:18

and natural coffees. In

32:20

2014, I was in Peru, running

32:22

yeast fermentation trials on cacao, in

32:24

addition to coffee. I was opening

32:27

the cacao pods to remove the inner seeds for

32:29

fermentation. This is the equivalent

32:31

of the pulping step in coffee, basically removing

32:33

the outer layer to expose the inner seeds. Most

32:37

of the pods were cut open and the cacao

32:39

seeds were easily scooped out. But

32:41

suddenly, I opened a pod that looked like it

32:43

had been infected with worms. Not

32:45

like little maggots, but long and thick

32:47

worms winding themselves around these seeds.

32:50

But the cacao wasn't infected with worms.

32:53

It turned out the cacao was quite mature.

32:55

It was the end of the harvest, and the seeds

32:57

were already germinating, and the radical,

33:00

the baby roots, were pushing their way,

33:02

were forcing their way out inside

33:04

of the closed cacao pod. I

33:07

don't think you will ever see this in coffee. Because

33:09

the outer peel, In coffee, the cascara

33:12

inhibits the seed from germinating.

33:14

If the outer peel is still on, it's

33:17

a signal to the seed that it's not an appropriate

33:19

time to use its resources to

33:21

become a new plant because conditions

33:23

are not correct yet. However,

33:26

when the coffee cherry is pulped, when the outer

33:28

skin is removed, the inner mucilage layer

33:30

is exposed to microbes in the environment, which

33:33

break down an additional protective

33:35

layer. When the outer layers

33:37

are removed and there is high humidity, the

33:39

seed has better chances of becoming a new plant.

33:42

So washed coffees, lacking their restrictive

33:45

exocarp, have much higher rates of

33:47

germination than dry process, which

33:49

maintains its protective outer shell for several

33:51

weeks. Higher rates of germination

33:54

are positively correlated with a longer

33:56

shelf life. If the embryo is

33:58

dead, the coffee fades more quickly. You'll

34:01

see this when coffee seeds turn pale or even

34:03

white. But if the embryo is alive,

34:05

the material in the seed stays viable because

34:08

a whole point of the seed is to be a little lunchbox

34:10

to feed the embryo so that it can become a

34:12

new plant. As anyone will

34:14

tell you, coffee is dead. Cacao that has germinated makes

34:17

terrible tasting chocolate. We

34:19

are still trying to catch coffee in that sweet

34:21

spot when the embryo is alive and the seed

34:23

material is still viable, but

34:25

not wait so long that it tips into

34:28

the seed becoming a new plant. I think

34:30

this, this balance of trying

34:32

to find this sweet spot of, Enough

34:35

viability, but not too much, is

34:37

a skill that not many have explored in drawing. So

34:40

where does that leave us? Naturals and

34:42

washed coffees taste different because of the environment

34:45

and the microbes that ferment them, but

34:47

also they taste different because of what's

34:49

going on inside the seed as well as outside.

34:53

We give fermentation a lot of responsibility

34:55

for flavor quality, a lot of credit.

34:58

But it's a step that takes on average 12

35:01

to 48 hours, maybe in some extreme

35:03

cases 100 hours. But

35:06

what about the things that we do for two to three

35:08

weeks? like drying. The

35:10

thing that we do for that much longer

35:12

must have an increased capacity to

35:14

impact coffee quality. The

35:17

step that we have never questioned quality is

35:19

the roasting, where the transformation from

35:21

green to brown is obvious. Clearly,

35:24

what you end up with is better than where you started.

35:27

In fermentation, we have a similar chance

35:29

to create new flavor compounds and precursors

35:31

that don't exist in the genetics of the coffee.

35:34

The seed after fermentation is different

35:36

and more complex. And

35:40

in drying, once again, there is an opportunity

35:42

to create new compounds in the raw material.

35:45

A properly dried seed is transformed

35:48

and can be better than how it started.

35:51

Thanks for making it to the end of another episode.

35:53

On coffee drying, no less. And

35:56

like a good coffee seed, I hope you are a little

35:58

transformed from how you started. Will

36:01

you think of coffee drying differently now? What

36:04

questions do you still have about drying? Let

36:06

me know by joining our live discussions or leaving

36:08

a comment on Patreon. During

36:10

the live office hours is where we get to have these frank

36:12

discussions about our industry, and if you've

36:14

been looking for a way to learn more, consider joining

36:17

Patreon to connect with other awesome listeners

36:19

and help me make more episodes. This

36:22

is important to me because this podcast is

36:24

a community supported effort. If

36:26

not for the handful of you guys Who joined the community.

36:28

This podcast would not exist. And

36:30

if you can't join right now, I still hope that you enjoy

36:33

listening and get value out of our time together,

36:35

and maybe you can share it with a friend to

36:38

be notified when the next episode is coming up, consider

36:41

subscribing to my free and infrequent newsletter

36:43

at Lucia. coffee. Lucia is

36:45

L U X I A. It's

36:47

great to be with you again. And remember life's

36:50

too short to drink bad coffee.

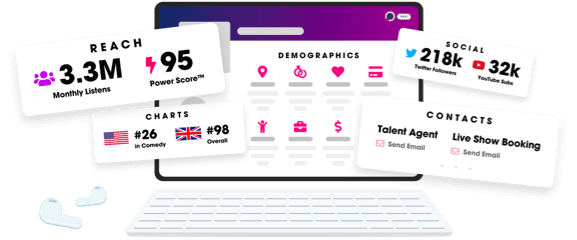

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us