Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:03

This is the Discovery Files podcast from the U.S.

0:06

National Science Foundation.

0:10

Concrete is the most widely used construction material in the world.

0:13

It is the backbone of what is called the built environment.

0:16

A crucial ingredient for housing and infrastructure development.

0:19

Advances in materials science and processing can enhance the long term

0:23

durability of many building materials, including concrete,

0:26

enabling significant economic and societal benefits.

0:30

We're joined by Sabbie Miller, an associate professor in the Department

0:33

of Civil and Environmental Engineering at the University of California, Davis,

0:37

whose research is dedicated to advancing the built environment

0:40

through the development and optimization of infrastructure materials.

0:43

Professor Miller, thank you for joining us today. Thank you so much for having me.

0:46

So I want to start with kind of defining one of the terms

0:49

that’s kind of key to what we're going to be talking about today.

0:52

What is the built environment?

0:54

So folks do use the built environment in a couple of different ways.

0:57

But typically what they're referring to is basically all of our buildings.

1:01

So houses apartment buildings, hospitals, school buildings, offices,

1:07

as well as all of our infrastructure systems and roadways.

1:10

So sewers and highways and all of those things together

1:14

are the environment that we as humans are building for ourselves.

1:17

And so it's often referred to as a built environment.

1:19

The most common material is concrete.

1:22

So we're going to be talking about a lot of concrete today.

1:25

I want to start with the manufacturing process.

1:27

What are kind of the problems with manufacturing currently?

1:31

So there's a couple of things to think about with concrete.

1:33

Yes, it is our most consumed building material worldwide.

1:37

It's actually a composite material. So it's made out of cement, water

1:42

and crushed rocks, which we refer to as aggregates.

1:45

So sometimes cement and concrete are used as synonyms.

1:48

But in reality, cement is this powder that reacts with water and holds together

1:52

rocks to make the synthetic rock that we refer to as concrete.

1:57

And some of the manufacturing challenges associated with the production of concrete are actually tied to that cement.

2:03

So when we're worried about things like the environmental burdens

2:06

for concrete, it's a function of a couple of things.

2:08

One, we use a heck of a lot of this material.

2:10

So whenever you use a lot of something, it's impact scale accordingly.

2:14

The other side of that being that the production of cement

2:17

requires the utilization of limestone, that's our main ingredient

2:21

in the production of cement. There are other ingredients as well.

2:24

But that limestone, to create that reactive compound that could interact with water,

2:28

we actually have to carbonate it. We actually have to break off effectively carbon dioxide from that limestone.

2:34

And that leads to a direct emissions from a chemical conversion.

2:38

And then on top of that, to get the reactions to take place,

2:41

we require thermal energy. So then we also have energy derived emissions tied to the production

2:46

of cement. So when we're talk about the impacts of concrete,

2:50

oftentimes the impacts are things tied to cement that we're worried about.

2:53

We hear about a lot of buildings when they get torn down

2:55

going straight to the landfill. Can we crush them and reuse them?

3:00

As an aggregate, let's say in any new concrete?

3:02

Or is there issues with that carbon cycle and the bits of the cement that you just

3:07

explained chemically that make it so we can't really do that?

3:10

It's a yes and no response to that. We can crush our concrete and get some benefits out of that product.

3:15

One of the benefits, actually, is that we really increase the surface area to volume ratio.

3:20

And if we have proper exposure to atmospheric CO2,

3:24

the hydrated cement in that concrete actually has a chance to interact

3:28

with the CO2 that's in our atmosphere and pull a wee bit back out.

3:31

The other thing, though, that we end up seeing from our crushed concrete is exactly as you mentioned.

3:36

It's made out of hydrated cement and aggregates,

3:40

which means it's not the same performance as the aggregates alone.

3:43

It's now got this like caked on hydrated cement stuck on the material so it doesn't have the same performance

3:49

as our normal aggregates that we would normally crush and use in our concrete.

3:54

As a result of that, it doesn't always necessarily perform the way we want it to in a new concrete,

3:58

but we are able to use it for sure in certain applications.

4:01

So for example, in California, where I am, I know that our Department

4:05

of Transportation actually uses the concrete from the roadways that we have,

4:09

crushes it up, and uses a road base for the new roadway

4:12

that they're about to put in, because it has great performance characteristics for that.

4:16

So we can use it in some ways, but not all ways.

4:19

So thinking about potentially reusing it for structural purposes,

4:22

it might have a weaker fracture value or something.

4:25

Yeah. The paste itself can have certain performance characteristics

4:29

associated with it. The cement that's interacted with the water and created this kind of binder material,

4:33

the aggregate is going to have certain performance. And then there's what's referred to as the interfacial transition zone.

4:38

This region where the cement is actually bound onto the aggregates

4:41

that has its own micro structure associated with it.

4:44

So yes, we end up with potentially different fracture performance associated with that.

4:49

Other types of durability issues can also be tied to having

4:52

this effectively, like a three phase material as opposed to just the aggregate.

4:56

So yeah, there's a couple of different issues that could happen that might hinder use in certain applications.

5:01

So the paper that kind of brought your work to my attention

5:04

is looking at using building materials for carbon storage.

5:07

So how might that be possible?

5:10

There's many different ways. So many of our building materials are already carbon based right.

5:15

They're already using carbon. It's not necessarily carbon that we've pulled out of the atmosphere,

5:20

but it is carbon. So part of what could happen is if we're able to re-engineer

5:25

those materials such that the carbon that's in the material is coming from a direct air capture system, or we're basically pulling

5:32

atmospheric CO2, concentrating it and then using it in those materials.

5:36

Then we could potentially store them for a really long time in the built environment.

5:40

The other way we could do that is capturing flue gas.

5:43

So carbon capture, actually trying to capture the CO2

5:47

as it's coming out of industrial processes, energy generation processes,

5:51

and then again, concentrating it, using it in our built environment

5:55

as the carbon source and potentially even having the materials

5:59

themselves directly capture carbon dioxide from the atmosphere.

6:03

This happens a little bit more with our biogenic materials, materials

6:06

that are living organisms, like our photosynthetic materials.

6:09

So if they're able to already interact with the atmosphere

6:12

through photosynthesis, they can pull in carbon.

6:15

And then we could use that material as something in the built environment.

6:18

So there's a couple of different ways to get that carbon stored in our materials.

6:22

But it depends on the material that you're talking about.

6:25

I know part of the study you were looking at the effectiveness

6:27

of different kinds of blocks like concrete, brick, asphalt, plastics, woods.

6:32

Can you talk a little bit about the effectiveness of these different forms?

6:36

Yes. So depending on the amount of carbon that you could put in any material,

6:41

you're going to have a certain degree of potential effectiveness

6:44

based on the carbon content. Right. So this is a very high level of carbon for this material.

6:49

So in theory we could store more carbon in this material on a weight basis.

6:54

The other thing though that we found was a much larger driver than that

6:57

component was how much of this material do you plan on using?

7:01

So even if you're getting less carbon stored in the material,

7:04

but you could scale it to an enormous quantity, like concrete,

7:08

then potentially you have this huge body that could store carbon dioxide

7:13

as long as you're getting desired performance out of the material.

7:16

So if the material has any loss in strength or the ability to place it

7:21

during construction, or if it fails earlier than our conventional material,

7:26

then you could end up not seeing these benefits.

7:28

So the performance of the material is always priority.

7:31

The idea, though, is that if we're able to get equivalent

7:34

or better performance out of these materials and store

7:37

atmospheric CO2 in them, we could have this really net benefit

7:40

of leveraging this huge mass of materials that is available to us.

7:44

One of those materials that I was curious to ask you about is bioplastics,

7:49

because we hear about plastic and think about it being like more of a manufactured toxic thing.

7:53

What is a bioplastic? So bioplastics are plastics where the carbon and the long

7:58

chain molecule that makes up our plastics is coming from a bio resource

8:02

as opposed to a petroleum based resource.

8:04

So the vast majority of our plastics that we interact with are coming from

8:08

petroleum based resources. That's where their carbon is coming from.

8:11

But instead, if we're able to use things like food waste, not priority food,

8:15

not food that we would otherwise eat, but waste that we would have otherwise

8:18

disposed of, or residues from, different agricultural or forestry practices.

8:24

So a biomass that we otherwise need to get rid of isn't

8:27

going to be a priority for something else in terms of its utilization.

8:31

If we could use those as the source of carbon,

8:34

then we could potentially reduce our dependency on petroleum

8:38

and leverage a bio resource that has pulled CO2 out of the atmosphere.

8:42

We might have access to it a little bit more

8:45

locally because of the ability to use different types of bio resources.

8:48

So there's a couple of different strategies that one could use, basically leveraging

8:53

that source of carbon to replace

8:56

our more petroleum based carbons and those materials.

8:59

Would this be like, say in the corn industry, like the husks or something that probably

9:04

you don't have a lot of use otherwise but could potentially be used in this way?

9:08

Exactly. So it's not the kernels that we would otherwise want to eat.

9:11

But yes, the husks, straw leaves, all of those sorts of things

9:15

that would otherwise be cultivated but not necessarily have as much value.

9:19

Now, I will note that we don't want to take all of that off of the farmland,

9:22

because farmers actually do need some of those nutrients to go back into the soil.

9:26

But if it is already being removed, then that type of biomass can be really valuable for products like bioplastics.

9:32

Interesting. One of the other things I wanted to ask

9:34

you about was geo polymers and their use in kind of alternate cements.

9:38

Can you talk a little bit about what these things are?

9:40

Yeah. So there's a class of alternate cements that are referred to as alkali

9:45

activated materials. Basically it's leveraging two main components a aluminum silicate

9:51

solid precursor. So something that has a lot of aluminum and silica in an amorphous

9:56

kind of like a chaotic, crazy state, not very well

9:58

aligned in a crystalline state, along with alkali activators.

10:02

When those are combined appropriately,

10:05

then we can actually create something that acts like a binding material,

10:09

just like our regular conventional cement with water.

10:12

So we're basically able to replace our normally highest CO2

10:17

component of concrete with something that doesn't require the same decarbonization of limestone, nor

10:23

does it require that same energy demand that our conventional cement requires.

10:28

So if we're able to replace that, there's this idea that potentially we could reduce a lot of the impacts

10:32

that we would normally associate with our cement and our concrete.

10:36

Geo polymers are a subclass of alkali activated materials.

10:40

So they happen to be one of the ones that's really well studied.

10:43

But it's in that class of materials that have these two key components

10:47

associated with them. And there's a lot of work going on right now trying to understand

10:50

where can we get those aluminum silicate solid precursors,

10:54

where can we get those alkaline resources such that they are globally available

10:58

and they themselves don't have high impact?

11:00

Because if we have to process them a lot, then we could kind of counter our own benefits.

11:04

That was going to be my next question, like trying to think about that for people

11:08

that aren't too specific about the chemistry there,

11:11

can you talk about something that might be an example of what that ingredient would be?

11:15

So our most commonly used alkali

11:18

activators would be things like sodium silicates and sodium hydroxide.

11:22

We use those kind of alkali resources in a bunch of other applications as well.

11:26

In terms of the solid precursors, a lot of work is looking at things

11:31

like the utilization of coal fly ash and, ground granulated

11:35

blast furnace slag, which we already use in the cement and concrete industry.

11:39

Coal fly ash is actually it's exactly what it sounds like.

11:42

So we use coal for the generation of electricity in many parts

11:45

of the world, and the vast majority is carbon.

11:49

That's what we're trying to oxidize to get our energy resources.

11:52

But there's a bit of mineral in that coal, and the minerals are going to contribute

11:56

to the formation of ashes, and some of the ashes

11:58

will settle down to the bottom, others will fly upwards.

12:01

And the ones that fly upwards are a bit fly ash.

12:04

And those ashes actually have a really desirable characteristics

12:08

associated with them. For this kind of perspective of utilization of aluminum silicates,

12:12

they have great characteristics for reactivity, a nice disordered

12:15

structure, etc.. So that's one class of these types of materials.

12:19

The blast furnace slag that I mentioned is actually a byproduct

12:23

of the treatment of iron oxide to form iron.

12:26

So iron is our main precursor to the formation of steel.

12:30

But we use iron and other things as well. Steel obviously has like a wee bit of carbon,

12:34

so we get better performance out of that material

12:36

when we're trying to make things like iron.

12:39

We usually start off with something like iron oxide,

12:42

and then in order to make that iron product,

12:45

we actually have to send it through a furnace. The utilization of, certain types of compounds

12:49

within the furnace, particularly a lime to purify that overall material,

12:55

leads to the formation of a slag byproduct.

12:57

So we're still getting our iron, but we've also got this

12:59

byproduct associated with the general process.

13:01

It also has fantastic characteristics the slag does for use in things

13:06

like the production of our alkali activator materials

13:09

or the use in concrete, because it can interact with the hydration process.

13:13

So there's a couple of uses of these industrial byproducts

13:16

that can get leveraged. There's also a bunch of other resources though as well.

13:20

So a lot of our agriculture products have a wee

13:24

bit of mineral in the biomass itself.

13:27

So again, not the food, but those residues like the corn husks, like rice straw, etc..

13:31

When we use those biomass products, it's predominantly carbon again.

13:36

But if we tried to recover energy from the biomass

13:39

through something like oxidation, we could then take the mineral compound

13:43

that's left over as an ash form and use it as a solid precursor

13:48

for the formation of alkali activated materials.

13:50

So there's a couple of different sources that we have worldwide.

13:53

And our current estimates suggest that if we wanted to replace Portland

13:58

cement, Portland cement as our conventional cement

14:00

with something like an alkali activator material,

14:03

about two thirds of our current demand for cement could, in theory, be replaced.

14:08

If we're able to leverage all of these different types of residues

14:11

the industrial byproducts, the agricultural residues,

14:15

forestry residues, if we're able to really utilize those properly,

14:18

we can actually start to make a pretty notable dent in the material.

14:21

Again, assuming that we get the right performance, we do need to engineer these things

14:25

so that we get what we need out of the materials.

14:28

So as you develop these kind of different materials,

14:31

is there kind of trouble getting industry to buy in with using byproducts

14:36

and using different kind of techniques to get at these things?

14:39

They've traditionally used with limestone and Portland cement?

14:43

Yeah. So engineers are very focused on performance for good reason.

14:48

We want to create products that work.

14:50

That is our main goal and are a little bit of tweaking to make them work

14:54

even better is also one of our big goals.

14:56

That said, civil engineers tend to be on the even more risk

14:59

averse side than conventional engineers.

15:02

We really try to make sure that things are working properly.

15:04

The reason for that being things like life safety issues,

15:07

you don't want to hop on a bridge and have it collapse or have a building collapse.

15:10

We really want to make sure our systems are working incredibly well,

15:14

and we use a few things to make sure that we are reducing risk.

15:17

A lot of probabilistic modeling, trying to understand exposure conditions,

15:21

trying to understand how we could best design these systems to reduce

15:24

likelihood of any type of failure associated with them,

15:27

and also our historic knowledge.

15:30

I put this material in here 20 years ago.

15:32

It's still doing great. I'm comfortable using it again.

15:35

That ends up being a really strong driver. Also, validation from other parties that other person use this material.

15:41

It was really successful. That means I have a higher likelihood of it being successful.

15:46

As you can imagine, incredibly valuable.

15:48

We don't want to remove this idea of minimizing risk.

15:51

We want to make sure that safety and performance are number one always.

15:55

But if you come up with a brand new material

15:58

that there's a little bit of a version of using it, because this kind of knowledge

16:02

of how it's going to perform and comfort associated with its use

16:06

isn't necessarily there. So we end up seeing that civil engineers are a little bit less likely to rapidly

16:11

adopt novel materials, because we need those materials to perform well.

16:15

So that we make safe structures, and we need them to perform

16:18

well for a long time. They have to keep going for decades

16:22

because there's a lot of work going on right now trying to understand how we improve adoption

16:27

of alternative materials, how do we make sure

16:29

that we have the proper validation so that we're removing that risk

16:32

from the practicing engineer? They should not be the one who has to take that on.

16:35

Do we change our overall insurance structure

16:38

so that there's more comfort trying to use some of these materials?

16:41

Should we change how we're structuring kind of later

16:44

stage testing so we're better understanding durability.

16:47

Is there something that we can do in order to understand any type of barrier for actually placing the material?

16:53

All of that is a really active area of research.

16:56

Everyone's really excited about AI right now.

16:58

Are you guys using AI in your lab as part of any of that kind of analysis process?

17:04

It's a tool. Engineers love tools.

17:06

So yes, we do use AI machine

17:09

learning algorithms in order to kind of help predict certain things.

17:12

So rather than conducting test over test over tests

17:16

so that we get a battery of information,

17:18

there are researchers around the world who are collecting fantastic information.

17:22

So yes, we are leveraging things like AI in order to use many different

17:26

data sets that might not all have been performed in the exact same way as such,

17:30

that we can still predict robustly the likelihood of material performance.

17:34

And we're also leveraging it to inform things where we have otherwise

17:38

data poor environments. So quantifying environmental impacts, for example, is a very and data

17:43

intensive field. And sometimes we have gaps in some of the inputs that are necessary.

17:48

But we can leverage AI to fill in some of those gaps.

17:50

Still with a bit of uncertainty, but better than our just guessing.

17:53

And then also we have utilization of AI for some, overcoming barriers

17:58

for adoption, trying to understand, okay, we have very limited data

18:01

for these particular types of performance metrics.

18:04

How can we predict what we would expect behavior to be, or predict what tests

18:07

we should be doing in order to fill in some knowledge gaps in that realm as well?

18:12

I also wanted to ask you about NSF support.

18:15

What difference has say your career award made for you?

18:18

NSF support has been the best support that I've had in my career.

18:21

I realize that that kind of sounds like I'm pandering.

18:23

At the same time though, NSF support actually allows us to do this

18:27

kind of more foundational, understanding type research.

18:30

NSF has facilitated my group actually looking at new areas

18:35

where we don't have a solid understanding of how this could pan out,

18:39

or where we should be focusing our attention.

18:41

So it has facilitated work, like the work that we've been discussing about what would potentially store carbon

18:47

and where could we get the biggest bang for our buck in terms

18:50

of trying to utilize carbon in the built environment?

18:53

And we end up seeing that NSF has actually been incredibly valuable

18:57

in trying to support that type of really groundbreaking work.

19:01

Put on a speculative hat for a second and think about

19:05

where would you like to see cements or concretes in, say, 75 years?

19:09

I'm a bit of an optimist, so I would like to see them having

19:14

higher performance characteristics so that we don't need quite

19:17

as much of the material. Obviously, we can't get rid of all of it because there's only so much

19:21

you can cut back and still get the right amount of roadways, buildings, etc.,

19:24

but higher performance characteristics out of the material.

19:27

I would love to see the material, obviously, at least at net

19:30

zero emissions associated with it, but also ideally something

19:34

that could be a net uptake, a net storage system for our environment.

19:39

And I would love to see more on circularity of resources tied to our use of concrete.

19:44

So just like you mentioned, this kind of use of concrete, crushing it

19:47

and getting to use it again, we haven't been big on resource circularity in general.

19:51

Not calling out concrete, but in general, humans

19:53

have been a little bit more linear and the life cycle of our materials.

19:57

We’ll extract, we’ll process, we’ll use, we’ll dispose.

20:00

I'm really excited about the kind of concept of how we can start

20:03

to re-engineer things so that when we're taking it out of use,

20:07

let's use the resources again such that they're circling through our economy.

20:11

Perhaps not straight into the same class of materials

20:14

or the same class of products if we are losing performance.

20:16

But how can we start to reuse those resources so that we don't have to keep extracting resources,

20:22

which would facilitate our potentially being able to continue building in a very robust way.

20:27

So for the very last question today, I want to ask you about what's next in your work.

20:31

We actually are continuing doing work in circularity

20:34

because I find it so exciting, also because there's some issues tied to resource consumption

20:38

and localized scarcity. So we might end up having areas around the planet where we have plenty of the material globally.

20:44

But in this particular area, we don't have enough access to it.

20:46

Now, we've got to import it from other areas, which can cause a variety

20:50

of different stressors on the environment as well as other types of stressors.

20:54

So trying to better leverage the resources that we're taking out of use,

20:57

that circularity is something that we're incredibly excited about in the group.

21:01

We're also looking at paired material and energy systems.

21:04

So humans are fans of energy, electricity in particular, and trying to understand,

21:09

okay, if we are going to need to continue to produce electricity,

21:13

how can we make sure that we have access to that electricity while also creating

21:17

co products that benefit other types of systems, such as materials production?

21:21

How can we pair those together such that we're able to generate energy

21:25

and create a net storage mechanism tied to that energy generation?

21:28

So we're getting the benefit of our energy resource,

21:31

but also removing CO2 from the atmosphere or undoing air pollutant issues

21:35

that we’ve sent into the atmosphere, trying to integrate those together.

21:38

And then of course, continuing work on decarbonizing materials production

21:43

and creating net uptake, net storage systems,

21:45

those are areas that I'm incredibly excited about.

21:48

Special thanks to Sabbie Miller. For the Discovery Files, I'm Nate Pottker.

21:52

You can watch video versions of these conversations on our YouTube channel by searching @NSFScience.

21:57

Please subscribe wherever you get podcasts and if you like our program, share

22:00

with a friend and consider leaving a review. Discover how the U.S.

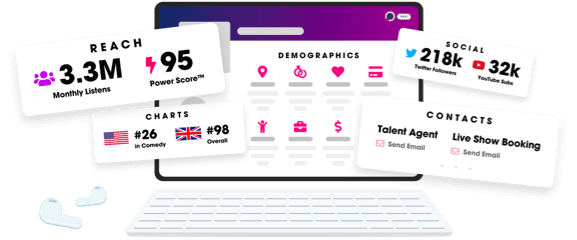

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us