Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Good day friends , fellows , country

0:03

people , happy to have you join us

0:05

today . Now in this episode

0:07

we're following up part two

0:09

, so to speak , of our feature

0:12

on circular economy

0:14

and what that could mean for Alberta and Canada

0:16

. Today we're going to sit down with

0:18

Nate , our pals over there doing

0:20

some really cool work with post-consumer

0:23

recycled plastics . Sit

0:25

back , settle in . Welcome to Shift . My

0:48

guest today is NAIT Applied Research

0:50

Lead , dr Mohamed Arshad

0:52

. Dr Arshad , it's very nice to see you

0:54

this morning . Thanks for joining me .

1:01

Thank you so much . It's nice to join you as well , for this podcast

1:03

.

1:03

So let's start right off at the top and

1:06

maybe I'll just get you to describe

1:08

what NAIT's Plastic Research

1:10

in Action program is all about

1:13

.

1:14

NAIT Plastic Research Action program

1:16

. Actually , this is a collaborative applied

1:19

research program between NAIT

1:21

and Heartland

1:23

Polymers . Part of it is from

1:25

interpipeline as well , with

1:28

the focus of finding ways

1:31

for innovative

1:34

solution for

1:36

circular economy to

1:40

, I would say , plastic

1:43

waste circularity . So

1:49

the main purpose is to

1:51

build a sustainable circular economy

1:53

. This

1:56

is a 10-year with

1:58

$10 million project where

2:01

NAIT researchers work with

2:03

Heartland Polymers to

2:05

develop solutions for

2:07

plastic recycling

2:10

and reuse .

2:12

I see , okay , and I'm going

2:14

to reference our listeners to a previous podcast

2:16

that I had

2:18

done with a colleague from Alberta Innovates

2:20

, mayor Niku , where she

2:22

defines circular economy and all

2:25

of that . So people go

2:27

give that a listen to as well , so you'll understand

2:29

what circular economy is about . And

2:32

then we'll continue along with Dr Arshad

2:34

. So now I understand that

2:36

you lead one of the programs within

2:38

the Plastics Research in Action program

2:40

, called now , this is a long title

2:43

. So here we go . I got to take a deep breath

2:45

Designing for Circularity

2:47

Development of Polypropylene

2:50

Blends Using Post-Consumer

2:52

Recycled Plastic . Got

2:54

to turn that into an acronym . Can

2:57

you tell me a bit about

2:59

that program , Dr Ashad ?

3:01

Yeah , this actually proposed

3:03

project . Actually , the main purpose

3:05

is to develop a technology platform

3:08

to produce polymer blends

3:10

using polypropylene

3:12

from heartland polymers mixed

3:15

with various commercially available

3:17

post-consumer recycled

3:20

materials or plastics

3:22

, while investigating

3:25

the effect of PCR contents

3:27

on the thermal , chemical

3:30

and mechanical properties of

3:32

the prepared blends , and

3:34

then provide a techno-economic

3:36

assessment for the most promising

3:38

formulations . Okay

3:41

, so those most promising formulations

3:43

you're talking about , those would then become

3:46

, ideally , a

3:48

product for consumers to purchase the

3:50

promising formulations and then by discussing

3:52

you know with our industry partners

3:55

how the properties

4:07

of these projects can , these

4:09

products can meet the requirements

4:13

for the specific products . So

4:15

it all depends on the industry partners

4:18

. If , if the properties

4:20

these we are going to

4:22

develop the product , the properties

4:24

of that product , is what

4:26

they need , then definitely they

4:28

plan to go for their application

4:31

at some point . But

4:34

at this moment it is like

4:36

to find out most promising formulations

4:39

while evaluating the effect

4:41

of PCR contents

4:45

when we are mixing it with virgin polypropylene

4:48

.

4:48

I see yeah , so

4:51

let me just step back for a second . You said

4:53

the acronym PCR .

4:55

Post-Consumer Recycled Plastics

4:58

Ah , excellent Okay . I want to be clear on

5:00

that . Okay , so would you then say what you've

5:02

just described are the goals of the program

5:04

? To find those formulations .

5:06

Yeah .

5:07

Okay to find those most positive formulations

5:09

, and what sort of timeline do you have in

5:12

mind for this ?

5:15

This project actually consists

5:17

of initially bench

5:20

scale and then we have

5:22

completed almost all the bench

5:24

scale phase and now we are

5:26

planning to go on the pilot scale . So

5:29

we will see how the results will

5:33

come up on the pilot scale and we

5:35

are in connection with our industry partners

5:37

, sharing all the details with them

5:39

and we'll see how this goes along , but

5:42

I'm expecting it may be

5:44

one more

5:46

year , because we already have spent two

5:48

years on this one and I think one

5:51

more year will be a suitable

5:53

time to complete this project .

5:56

Okay , so bench scale is . That

5:58

was the first part . You've completed that and you've

6:00

said this has gone on for a couple of years now

6:02

. Yeah , and then you move into the pilot

6:04

phase .

6:05

Yeah .

6:06

So then , does that mean that you have

6:08

some formulations of

6:10

the polypropylene and post-consumer

6:13

recycled product that you've put together in

6:15

that bench phase and are now going to pilot

6:18

test them ?

6:19

Yeah , this is what we did yeah .

6:22

Okay , and remind

6:24

me the name of the industry partner

6:26

that you have Heartland

6:28

Polymers , heartland Polymers

6:30

, okay , yeah . So now

6:33

I want to step

6:35

back a little bit and give people a general sense

6:38

of kind of the life cycle of plastics

6:40

, because plastics are so

6:42

ubiquitous and such a part

6:45

of our lives and you know we've

6:47

been trained to . You know , reduce

6:50

, reuse , recycle . So we

6:52

, you know , as good citizens , we wash out

6:54

our plastic food containers and we put them in

6:56

recycling , thinking that that product

6:58

then goes off somewhere to become

7:00

a post-consumer recycled product

7:03

. I'm going to lean on you a little

7:05

bit here to tell me the reality of

7:07

the life cycle of plastic .

7:10

Yeah , sure you

7:13

know , when we talk about

7:15

the life cycle of plastics it starts

7:17

from production until

7:19

it gets into waste and then bringing

7:22

back to circularity

7:24

or , in a closed

7:27

loop , to recycle it . So

7:31

it starts from production and initial use . So what exactly happens in the

7:33

production ? These

7:35

plastics are made from either petroleum

7:39

or natural gas , where they go

7:41

some chemical

7:43

, where

7:47

they go some chemical processes to prepare polymers and those polymers actually further

7:49

blended and injection molded into

7:51

various products

7:54

which can be used for various

7:56

applications , ranging from packaging

7:58

materials to automotive parts

8:00

. So after manufacturing

8:03

, when these plastics serve

8:06

for their intended purpose , such

8:09

as food containers or bottles

8:11

or household products , so

8:14

once they are used , they become

8:17

post-consumer waste . So

8:20

they are often disposed in recycling

8:22

bins . They

8:27

are often disposed in recycling bins , okay , and after that , when they

8:29

are disposed into recycling bin , the next step is collection and

8:31

sorting process . So you know recycling facilities

8:34

. They collect plastic waste , but

8:37

we know all plastics are not recyclable

8:40

, so they have to , you know , sort

8:42

each plastic

8:44

by type and quality . So

8:47

after this process

8:49

, you know all

8:51

these plastic waste also has some contaminations

8:54

coming from foods and some other sources

8:56

. So after this it is after collection

9:00

and sorting , they are actually go

9:02

to the next step , which is processing and cleaning

9:04

. So these starting sorted

9:07

or separated plastics are further

9:10

cleaned to remove any contamination

9:12

and then shredded into

9:14

flakes and those flakes

9:17

are actually melted into

9:19

pallets forms

9:21

, and those pallets are actually the

9:24

raw materials which we named as a

9:26

post-consumer raw material that

9:28

can be now further used to

9:31

develop

9:34

a product . I

9:37

would say those

9:39

raw material will go in a remanufacturing

9:41

process . So in the

9:43

remanufacturing process these

9:46

pallets are blended with

9:48

virgin poly polymers

9:51

or with some additives

9:53

to get again the desired

9:55

properties , so that these raw

9:58

material , after mixing with virgin

10:00

polymers or other you know

10:02

additives , they can be used again

10:04

for the same purpose as

10:07

they were designed and used for the

10:09

first time and

10:11

and that's what you're doing with Heartland

10:13

is you're taking these post-consumer recycled

10:16

pellets and

10:18

introducing them to the virgin polypropylene

10:22

that Heartland has . Yeah .

10:24

Okay , so a couple of things you

10:27

had said . Some plastics aren't

10:29

recyclable .

10:30

Yeah .

10:33

And then my second question . I

10:35

just have to say this , get on record before I forget

10:37

is what

10:39

? Why can't we make products with a hundred

10:42

percent post consumers ?

10:43

yeah , that's very interesting question you know

10:46

, I can give an example that why

10:48

some plastics week it's hard to recycle

10:50

or we cannot recycle , especially

10:53

if we take an example of multi-layer

10:55

packaging materials . So

10:57

, multi-layered packaging materials

10:59

, they are actually made up of different , sometimes different

11:02

, type of plastics , right , and it

11:04

is hard to

11:06

sort out , to separate them for

11:08

better recycling purposes . And

11:11

some plastics they have a

11:13

contamination which is hard to

11:15

get rid of that contamination and

11:18

that would automatically impacts the properties

11:20

, affects the properties

11:23

. So that's why it is

11:25

it makes hard to

11:27

recycle such type of plastics

11:30

. And when we say about the

11:32

second question you asked about why

11:34

we cannot use 100

11:36

percent pcr plastics , we

11:39

can use 100 percent post-consumer

11:41

recycled materials in the development

11:43

of different products . But

11:45

there are some problems that we

11:47

may not be able to use it for

11:53

the same application it was designed

11:55

for at

11:59

the time of its first use

12:01

. It

12:04

was intended

12:06

to produce or

12:08

develop at the first time . The reason

12:10

is because after

12:13

going through multiple cycles

12:16

they actually lose their quality

12:18

. So when they lost their quality

12:21

it is hard to use

12:23

the PCR material

12:25

again for the same type of products

12:29

. In that case , because they lost

12:31

their qualities , we have

12:33

to downgrade or downcycle that

12:35

material

12:38

into low value products because

12:41

of their , you know , compromised

12:43

quality .

12:44

Okay , okay , so that's the

12:47

idea of why we introduce some

12:49

virgin polypropylene . Yes

12:52

, so we can kind of strengthen it .

12:54

Yeah , strengthen it . To get the

12:56

desired strength and

12:58

durability , we mix it with

13:00

virgin polymers

13:02

.

13:03

I get you . Okay

13:05

. So if we went 100% post-consumer

13:08

recycled plastic , if it was a car

13:10

part at one time , we couldn't

13:12

use it as a car part again because it's

13:14

not going to be as strong , for

13:16

example . Yeah , that's true .

13:18

Because you know , after multiple processing

13:21

and passing through different you know

13:23

conditions like temperature

13:25

and processing parameters , they

13:28

lost their properties . That is

13:30

the reason it is hard to use them

13:32

again for the same purpose it was prepared

13:34

for . So because their

13:36

qualities are compromised . That's

13:38

why we may be able to prepare some

13:41

other products with low quality

13:43

, I understand .

13:45

Okay , so what happens to the plastics

13:48

that are that incorporate

13:50

multiple plastics that

13:53

can't be recycled ? Are they just

13:55

thrown thrown ?

13:56

away and the only , the

13:58

main concern in that case is uh

14:00

, when there are , you know , different type

14:02

of uh plastics when

14:05

we process all , all of them together

14:07

. Because each plastic has different type

14:10

of properties and

14:12

it is not only plastic . Sometimes

14:14

these multi-layer packaging has some

14:17

other type of materials as well , like

14:19

aluminum foil kind of

14:21

you know . It is also

14:24

one of the layer in multi-layer packaging

14:26

. So different type of materials

14:28

in that plastic packaging . It

14:31

is hard to , you know , melt

14:33

them together and then get the

14:35

desired product for application

14:37

. So first of all we need to separate

14:40

those all plastics and

14:42

then we can , you know , after

14:44

separation , we can process them for

14:46

recycling purposes . So here

14:49

is the challenge how we will separate

14:51

these different multi-layer

14:53

packaging , different type

14:55

of plastics in

14:57

one package . So

14:59

that is the main reason , actually the main

15:02

problem here , the main challenge over here

15:04

to recycle those plastic

15:07

material .

15:08

So is that part of what your

15:11

program is working on is

15:13

to figure out how to extract all of those

15:15

.

15:17

We are actually not working

15:19

exactly on this specific

15:22

project under PREA , but

15:25

that is kind of one of the examples

15:28

to let the audience know

15:30

what actually the challenges

15:32

are in case of recycling

15:34

multi-layer packaging materials

15:36

.

15:37

Okay , okay , so that's the big sticky

15:39

one is the multi-layer

15:41

packaging materials . Yeah

15:44

, have you got some statistics that you can give our

15:46

listeners a sense of ? Like

15:49

recycled plastics versus , you

15:51

know , these multi-layer plastics

15:53

that aren't being recycled ?

15:56

Yeah , I was reading some

15:58

, you know , in the statistics

16:00

reports so

16:02

I have read like one of the reports says

16:05

that in

16:07

past two decades the production

16:09

of plastic itself has

16:11

doubled . Two

16:16

decades the production of plastic itself has in has doubled . So in that way , the plastic

16:18

waste amount is also twice in number as compared

16:20

to what it was

16:22

two decades ago . So

16:25

if we have a look like

16:28

, whatever the plastic

16:30

is being generated , only 9%

16:32

is being recycled , while the rest

16:35

of the amount is either going

16:37

to be landfilled or incinerated

16:40

, and that is automatically affecting

16:42

our environment , and some of

16:44

them leaked into the environment

16:46

as well . Sure .

16:48

Yeah , 9% , you said 9%

16:50

.

16:51

Yeah , yeah , nine percent . You said

16:53

nine percent . Yeah , only nine percent plastic is being recycled , while the

16:55

rest of the amount is either burnt

16:57

or , you know , landfill

16:59

or something it goes into the environment

17:02

, so definitely impacting our environment

17:04

. So that

17:06

is , yeah , that's what actually the

17:08

number is which is being recycled . So

17:11

we have to bring some .

17:13

yeah , that's a significant amount

17:15

that's not being recycled . Now

17:19

we've talked about Heartland and the role they're

17:21

playing . Talk to me a little bit more about partnerships

17:23

that you have with other stakeholders . Who

17:25

else is Nate working with in this regard ?

17:30

Yeah , regarding partnership with stakeholders

17:33

, you know it's very crucial for driving

17:35

innovations , improving

17:37

sustainability and ensuring

17:40

regulatory compliance

17:42

. So these partnerships can

17:44

you know include , as you are mentioning

17:46

, some other different you know industry

17:49

partners or our non-profits and consumers

17:51

. So

17:54

NET is working with different industry

17:57

partners and we have already worked on different

17:59

our industry partners , one

18:01

of them , in addition to Priya we

18:03

worked with ReWaste

18:06

that one also one of the company

18:08

we were working to reuse

18:10

some plastic waste , recycle

18:13

some plastic waste . We

18:19

are also working with the Alberta

18:22

beekeeping industry where we are trying

18:24

to recycle used

18:26

beehive foundations

18:28

which are made up of plastic

18:32

and once they complete

18:34

their life cycle , they can't

18:36

reuse it

18:40

, so they either burn it or they

18:42

may go into landfill . So

18:44

we are also looking into , you

18:46

know , solution how

18:48

we can recycle that plastic or reuse

18:51

that plastic . So that

18:53

is one of another project we

18:55

are working with Alberta beekeeping industry

18:57

.

18:58

Oh , that's cool . Yeah , I wouldn't have thought of that . Okay

19:01

, so it's a plastic foundation for beehives

19:03

. Is that what the apiaries

19:06

are using ? Yeah , oh

19:08

, neat . Tell me a little

19:10

bit about the impacts the

19:12

impacts of your work and Nate's

19:14

work on industry and the larger

19:16

Alberta community .

19:18

When we talk about , like plastic industry

19:20

, it has significantly

19:23

influenced Alberta's economy

19:25

community , presenting

19:27

both opportunities and challenges

19:29

. And

19:36

challenges when we talk about opportunities , we can see that

19:38

in a plastic industry it generates a lot of revenue and

19:40

also provides , you know , job opportunities to the individuals

19:42

in our community . So

20:15

in that way it is helping

20:17

, you know , creating opportunities

20:19

.

20:19

So even government also

20:21

has created , you know , initiatives

20:23

and , you know , greater influence

20:25

or impact on Alberta as well as community

20:28

as well .

20:28

But there's products there

20:31

, there's opportunity for entrepreneurs

20:33

to think about how these

20:35

products can be reused

20:38

, redeveloped as something else should

20:55

be spent or provided from industry , partners or governments so that the research

20:57

can be done to develop more innovative technologies

21:00

or finding pathways to

21:04

promote these sustainable

21:06

circular economy .

21:09

Yeah those opportunities yeah , I get what you're saying . Yeah , those opportunities yeah

21:12

, I get what you're saying . So

21:14

what can people

21:16

do ? What can listeners do to

21:18

mitigate or

21:21

directly

21:23

or indirectly support the activities you're

21:25

working on ? And also

21:28

that notion of plastic

21:30

recycling ? What can they do

21:32

to be more aware , maybe consume less

21:34

plastic ?

21:42

Yeah , there are several ways . Like individuals or businesses or communities

21:44

and organizations , they can support

21:46

plastic circularity and sustainability

21:49

in Alberta and beyond

21:51

. You know , know all over the

21:53

world . So I would say

21:55

like choose reusable

21:58

plastics or products over

22:02

single-use plastics . In

22:04

that way we can reduce plastic

22:07

waste . The other thing

22:09

is , when we are selecting

22:12

any product , it's good to

22:16

find out the product which contains

22:18

some recycled contents in it , so

22:22

that will also help to

22:24

reduce plastic . And the other thing is , again

22:26

, if we can choose biodegradable plastic

22:28

, that will be more

22:31

helpful in saving

22:33

our environment . And

22:35

also , in addition to this , I would say , follow

22:37

local recycling guidelines

22:40

to ensure that plastics are

22:42

disposed of correctly , because

22:45

you know contaminated

22:48

plastics , usually they go to landfills

22:50

and automatically they are going to impact

22:52

our environment .

22:54

Now , dr Arshad , I think let's

22:56

wrap it up . There's lots to think about

22:58

. Is there any final note you'd like to leave

23:00

us with , or any final

23:02

thing that we should consider ?

23:07

I would say , as

23:09

we have discussed in detail

23:11

about the recycling and circular economy

23:14

and we know that the

23:16

linear model of take

23:18

, make and waste is highly

23:21

impacting our environment and

23:34

bring more programs , funding programs , and bring awareness to the community so that

23:36

we can promote or enhance

23:39

more sustainable circular economy

23:41

. In circular economy

23:43

, where we don't , you know , waste and dispose

23:46

of material into landfills , we

23:49

bring it back to a closed loop

23:51

so that we can recycle it

23:53

and bring it back into , you know , reuse

23:57

for various applications and again and

23:59

again . For that , actually , I would

24:01

say , you know , government

24:03

, industry partners and different organizations

24:06

and communities should come together to

24:09

work on this

24:13

initiative of circular economy as

24:15

much as we can so

24:18

that we can save our environment

24:20

from these questions .

24:22

When you introduce that notion of circularity

24:24

, it's also again taking

24:26

something we normally treat as waste , as

24:28

a valuable resource . And now

24:30

what's the opportunity to create jobs ? What's

24:32

the opportunity to mitigate

24:35

our impact upon the environment ? But

24:38

there's a socioeconomic component too

24:40

that I think we could really develop

24:43

and create into a huge success . Dr

24:47

Arshad , I appreciate your time

24:49

and this was great . Your time

24:51

and this was great .

24:53

Yeah , thank you so much for

24:55

your time and

24:58

for inviting me for this podcast

25:00

. It was nice talking to you .

25:03

It was very nice talking with you as well , thank

25:05

you . Shift is brought

25:07

to you by Alberta Innovates . We can be found at your

25:09

favorite streaming service or online

25:12

at shiftalbertaainnovatesca

25:14

. Until next time , you

25:16

.

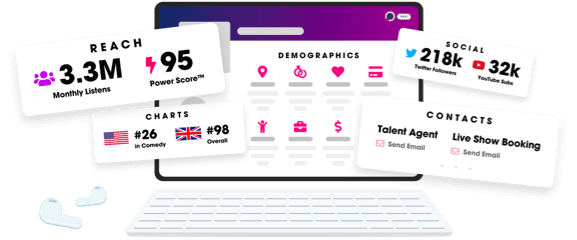

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us