Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

If you haven't set yourself up

0:03

to create a risk resilience supply

0:05

chain, it will cost you more.

0:08

It may shut down your plants. It

0:10

will cause impacts on

0:12

your consumers. So it's critical

0:14

part of a company that they'd be able to do

0:16

this to make the right decision in the near

0:19

term. Many of these

0:21

disruptive events, if you think about COVID, you think

0:23

about supply chain crisis, you think about the trade

0:25

tensions, effectively brought companies to a starting line and

0:27

said, go, go and

0:30

find alternative sources of

0:32

suppliers, go and find alternative pools

0:34

of talent, go find alternative locations

0:37

as you rebalance your business model. They

0:40

have to make sure everything is digitized, all

0:42

their data is relevant, reliable and

0:45

responsible. And if they can get

0:47

their hands around that, then they

0:49

really can take advantage of the

0:51

power of generative AI, which is a

0:54

game changer. From

0:57

PwC's management publication Strategy and Business,

0:59

this is Take On Tomorrow, the

1:01

podcast that brings together experts from

1:03

around the globe to figure out

1:05

what business could and should be

1:07

doing to tackle some of the

1:09

biggest issues facing the world. I'm

1:12

Ayesha Hazarika, a broadcaster and writer

1:14

in London. And I'm Lizzie

1:16

O'Leary, a podcaster and journalist in New

1:18

York. Today, how can

1:21

companies build resilient supply chains?

1:25

From the war in Ukraine to the

1:27

closure of the Suez Canal, to the

1:30

attacks on cargo ships in the Red

1:32

Sea, it's fair to say that in

1:34

recent years, global supply chains have been

1:36

disrupted. Not to mention

1:38

the impact of COVID-19 and continuing

1:41

inflation. And everyone has seen the

1:43

impact on business and society. When

1:46

supply chains are disrupted, consumers and companies

1:48

pay the price in more ways than

1:51

one. How supply chains responsible for more than 70% of

1:55

an organisation's cost base and emissions?

1:57

How can companies build more flexible, resilient

2:00

and adaptable supply chains.

2:03

To find out, we'll be talking

2:05

to Darcy McLaren. Darcy has decades

2:07

of experience in managing supply chains

2:10

and is currently Global Chief

2:12

Revenue Officer at SAP's Digital

2:14

Supply Chain Practice. But

2:17

first, we're joined by David

2:19

Widgeratsny, a partner from PwC

2:21

Singapore in the International Growth

2:23

Practice. David, hello, welcome. Thank

2:25

you very much. It's great to be here and looking forward

2:28

to the discussion. David, we've

2:30

just laid out some of the many

2:32

different challenges impacting global supply chains right

2:34

now. Do you think this is the

2:37

new normal that businesses have to adjust

2:39

to? I think so, actually. I

2:41

think we've entered a new

2:43

era. But since about early 2000,

2:46

we began to see the global economy begin to

2:48

shift. We began to see

2:50

companies start to address new

2:52

consumer pools that might sit in Southeast

2:54

Asia, for example, Africa,

2:56

for Latin America. Companies

2:59

begin to address consumer pools that

3:01

are outside of developed markets. Also,

3:04

characterized by the emergence of new

3:06

suppliers, thinking about how do we

3:08

identify new suppliers in Southeast Asia,

3:10

maybe Central Eastern Europe, maybe perhaps

3:12

Latin America. But

3:14

also, this era was beginning to

3:16

see rising cost factors, geopolitical tensions,

3:19

nationalism, increased use of technology

3:21

and AI, and the increased

3:23

importance of ESGs. All of

3:25

these characteristics are shaping

3:28

the new global economy. And

3:30

companies historically, prior to 2019,

3:33

felt that they could move on their

3:35

own agenda. However, ever since 2019, you've

3:37

seen companies beginning to realize that they

3:39

have to move, they need to change

3:41

their business model, and they need to

3:43

change it fast. Many of

3:45

these disruptive events, if you think about COVID,

3:47

you think about supply chain crisis, you think

3:49

about trade tensions, effectively brought companies to a

3:52

starting line and said, go, go and

3:55

find alternative sources of

3:57

suppliers, go find alternative pools of talent,

4:00

turn to locations as

4:02

you rebalance your business model. We'll

4:04

come back to you soon, David.

4:07

But first, with disruption to supply

4:09

chains worldwide, any business leader

4:11

listening to this must be wondering, where do

4:13

I even begin? Ayesha,

4:15

you spoke to Darcy McLaren,

4:17

Global Chief Revenue Officer at

4:19

SAP's Digital Supply Chain Practice.

4:22

That's right. I began by asking

4:24

just that, what is she telling

4:27

her clients to do? First

4:31

and foremost, we highly recommend

4:33

that you put supply

4:35

chain at the heart of

4:38

your business strategy, not an afterthought.

4:40

The second thing is to look at, is

4:43

really to make your supply chain

4:46

risk resilient. What that means is you

4:48

take a look at your organization and

4:51

then you understand, what

4:53

are the key constraints that are

4:55

most important to your business? Is

4:57

a key contract manufacturer? Is there

5:00

a key raw material? Is

5:02

there a critical region? You look

5:04

at these things and make sure that you

5:07

have contingency plans for them. It's not about

5:09

cost and efficiency anymore, it's

5:11

about risk prevention. Then

5:14

we recommend collaboration. That

5:17

means cutting down silos

5:19

internally and working across

5:21

your extended ecosystem and all your partners,

5:23

which means you have to have and

5:25

be digitally connected to everybody. Fourth

5:28

area we recommend is

5:30

embracing technology, such as

5:33

machine learning, predictive

5:35

artificial intelligence. Those

5:38

are really the areas that we recommend for companies

5:40

to take a look at in

5:42

risk-proofing and managing the disruption. Looking

5:45

at the challenges facing

5:47

global supply chains, do

5:49

you anticipate those challenges are going to get

5:52

better or get worse in the near

5:54

term? Great question. In fact, there

5:56

is a chart that the

5:58

Federal Reserve or the Bank of the York

6:00

puts out that actually tracks the

6:03

impact of global disruption and

6:05

the volatility. It absolutely shows

6:08

the volatility will increase. What's

6:11

interesting to note is the

6:14

recent one in the Red Sea, it

6:16

does appear that companies learned a

6:18

lot with the former disruptions

6:21

and we're now in a better position

6:23

to respond quicker, better,

6:25

faster, more sustainably because many organizations

6:27

have put in the technology to

6:30

allow them to respond quicker. So

6:32

I think that's the good news

6:34

going forward. Yes, disruption will continue.

6:37

Embracing technology can help you deal with

6:39

disruptions in a much more effective way.

6:42

And talk to us about the impact supply

6:45

chain disruption can have not just

6:47

on an individual business but on

6:50

wider society. It

6:52

ultimately leads to higher prices for

6:54

the consumer. It can

6:56

also increase the carbon footprint, which is

6:58

not good for the environment. And

7:01

also can cause trade disputes and

7:04

regional disputes. So

7:07

across from end consumer to even

7:09

inflation increasing is all affected by

7:11

issues with the global supply chain

7:13

not responding properly and not having

7:15

proper tools to do the best

7:17

we can in resolving it. How

7:20

have you found businesses

7:23

willingness and desire to adapt

7:25

to these challenges that

7:27

you've set forward? What's

7:29

happening now is yes, people realize

7:31

we have to change. We

7:34

have to have better collaboration, but

7:36

it's hard. What's interesting to

7:38

note is smaller company, new companies, they

7:41

don't have any legacy they have to

7:43

break down or bring with them and

7:45

they're in a much better position to

7:48

really transform to what we call a risk

7:50

resilient and sustainable supply chain. So

7:54

we're bringing customers with us, but

7:57

there's definitely going to be a change in

7:59

the world. the supply chain practitioner

8:01

from what it is today to

8:03

what it needs to be in

8:06

the future, it's massive change management

8:08

that's going through every organization right

8:10

now. And Darcy,

8:12

talking about customers, you help businesses

8:15

digitize their supply chain. What's the

8:17

difference between a digital supply chain

8:19

and a traditional one? So the

8:21

way I define it is a

8:24

digital supply chain refers to

8:26

the integration of digital technology

8:29

on supply chains. Ultimately,

8:31

you want to digitize everything

8:34

in your supply chain. So you

8:37

can do simulations, optimizations, and

8:39

then have the ability to

8:41

act on it. In order

8:43

to have what we call a self healing

8:45

supply chain, which is the ability to

8:47

get a piece of information in such as a

8:49

delay on ocean freight

8:52

into the system, have it understand

8:54

what that means to the customer

8:56

order, what you need to decide it. And

8:58

in order to do those automatic

9:00

self healing things in the supply

9:03

chain, you have to digitize the

9:05

organization. And where are

9:07

we in terms of companies

9:09

making this move to supply

9:12

chain digitization? Do people

9:14

get it? Are people willing to

9:16

do it? People understand

9:18

the need to do it. The

9:21

degrees vary greatly by company

9:23

by industry. A

9:25

lot of companies are starting

9:27

with visibility, getting everybody in

9:30

their ecosystem connected bi-directionally

9:33

to get visibility on what's going on.

9:35

So a lot of companies start with

9:38

digitalizing everything in the ecosystem.

9:41

But what we have to do is

9:43

digitize everything. And that includes all your

9:45

things and your things

9:48

that we need to digitalize all

9:50

your manufacturing equipment. So we're capturing

9:52

information on performance, on

9:54

quality. A lot of folks

9:57

digitalized most of their manufacturing

9:59

equipment. years ago, but the idea

10:01

is to now get it connected

10:03

and usable by the rest of

10:05

the organization. In terms of

10:07

companies being able to build resilient supply

10:10

chains, are there cultural

10:12

aspects to this? For example, do people,

10:15

component companies need to think

10:17

about upskilling for their employees, how

10:20

to make sure they've got the

10:22

right skills to make this process

10:24

happen, for example? All of the

10:26

above. There is going to be

10:28

a lot of skill changes as

10:31

to what you need in your organization and

10:33

the jobs are changing. And companies

10:36

are trying to upskill their employees

10:38

to bring them up to the

10:40

next level. So instead of actually

10:42

doing this, you're monitoring it. Warehouse

10:45

management folks work in conjunction with

10:47

a co-bot. They don't actually

10:49

do the forklift, but they have a

10:51

co-bot and they direct it. So there's

10:53

a lot of interaction and

10:56

there's definitely upscaling the

10:58

current employees as well as

11:00

changing the definition of the

11:02

role, bringing in a different

11:04

type of talent. And the

11:06

other thing we're trying to do is

11:08

we have a better of AI that

11:11

can explain to the supply chain practitioner,

11:13

the planner, exactly what

11:15

the AI did so

11:18

they can understand and it's not just

11:20

a black box. That helps in the

11:22

adoption, say, okay, I understand where it

11:24

got the answer. That makes

11:26

sense to me. And that's a way of helping

11:30

planners to embrace the technology when they're used

11:32

to making some of this decision on their

11:34

own and understanding the data a little bit

11:36

more. And then it's been a game changer.

11:38

Darcie, now let's look at what major

11:41

economies are doing such as China and

11:44

the US in terms of

11:46

onshoring and friendshoring key elements

11:48

of their supply chains. What

11:51

impact is this having both from

11:53

a business perspective and from a

11:55

society perspective? So what's

11:57

been happening now is as we evolved

12:00

from these supply chains that were

12:02

very cost effective,

12:04

efficient affected, single source,

12:08

that does not happen anymore. We

12:10

now realize that organizations

12:12

should not be single sourced

12:15

in any region for any part

12:17

for any contract manufacturer and that's

12:19

caused folks to look at

12:21

other options. It's why you have

12:23

organizations that are looking towards nearshoring.

12:25

We won't bring everything back here

12:27

because that would also cause problems.

12:30

So we have to have a blended

12:32

plan and so you can see companies

12:34

are starting to move things more back

12:36

to the US and certain states in

12:39

the US have made that very attractive

12:41

to do so and also I will

12:43

say technologies and advancements in industry

12:46

4.0 and manufacturing have made

12:48

productivity and some of the

12:50

labor constraints that we're keeping

12:52

US for manufacturing automation

12:55

can help with that. For all sorts

12:57

of reasons we're starting to look

12:59

at onshoring, nearshoring, alternative shoring

13:02

and yes that has an impact. The

13:04

Red Sea issue is one where

13:06

folks are trying to now figure

13:08

out can I change where I

13:10

get it from, do I go over land,

13:12

do I go around Africa and all that

13:15

and those decisions will keep on

13:17

happening and people will evaluate what

13:19

the right thing is to do but it is interesting what's

13:21

going on right now. Now let's

13:23

look at what's at risk

13:25

for businesses if they don't

13:28

embrace a technology driven supply

13:30

change. What are the

13:32

big risks for them Darcy? It's

13:35

quite simple. If you haven't set

13:37

yourself up from your sales and

13:39

operation planning to create a risk

13:41

resilient supply chain there's

13:43

not much you can do in the

13:45

short term. So what will

13:48

happen is it will cost you

13:50

more to transport your product. It

13:53

may shut down your plants because you

13:55

can't get certain parts in so

13:58

it'll cause plant. outages,

14:00

it will cause either

14:02

not enough inventory or too

14:05

much inventory. It will cause

14:07

impacts on your

14:09

consumers. So it's critical part of

14:11

a company that they be able to do this

14:13

to make the right decision in the near term.

14:16

And it takes technology. And do you

14:18

think our policymakers and our politicians and

14:20

the people who are in government,

14:22

do you think they think enough

14:24

about the importance of supply chain?

14:26

Pre-COVID? No. Post-COVID?

14:29

Yes. A lot has

14:31

been done to make sure individual

14:34

countries know the situation

14:36

and they're trying to make sure they're

14:39

protecting the best interest of their

14:41

organization. So in the US, for example,

14:43

it's all about rare minerals and making

14:45

sure we have access to that

14:47

for all our technology providers and making

14:50

sure we're protected. So we've

14:52

come a long way, still a lot to

14:54

do. And now what they're

14:56

trying to figure out, among other things,

14:58

is what are the impacts of generative

15:00

AI? They're going from

15:03

trying to risk-proof their countries from

15:05

a supply chain and now getting

15:07

very involved in technology and rules

15:10

and regulations and such in that

15:12

area. So it's a whole area of

15:14

itself. The governments are really trying to get up to speed

15:16

on to see what they can do. Now,

15:19

finally, Darcy, I'm going to ask you

15:21

to get your crystal ball out. What

15:23

do you expect over the next 12 months

15:26

to be the really big challenges facing

15:28

executives managing their supply

15:31

chains? The big challenge that

15:33

everybody is going to have

15:35

to get their hands around

15:38

is what do they need

15:40

to do to really embrace

15:42

and use business

15:45

AI to effectively

15:47

manage their supply chain?

15:50

And that means they have to make sure

15:52

everything is digitized, all

15:54

their data is relevant,

15:57

reliable and responsible. around

16:00

that, then they really can take

16:02

advantage of the power of generative

16:04

AI, which is a game changer.

16:07

Darcy, it's been so fascinating speaking with you.

16:09

Thank you so much for your time. Thank

16:11

you so much for having me. I appreciate it. Well,

16:16

David, Darcy was pretty clear

16:18

there that disruption is here

16:21

to stay. What kind

16:23

of moves do you see businesses making when

16:25

it comes to their supply chains right

16:27

now? Are they making a

16:29

big or reactionary or are they having a complete

16:32

total shift in how they think? So,

16:35

I think you can see companies acting in

16:37

two ways. One

16:39

is how companies look to mitigate

16:41

the risks that they are facing,

16:43

so de-risking their value chains or

16:45

de-risking their supply chains. So thinking,

16:47

how do we protect the value

16:50

pools that we have today by

16:52

looking for alternative suppliers, looking for alternative

16:54

manufacturing hubs to create a greater resilience?

16:57

Now, the danger with that is

16:59

that eventually, if you just purely protect

17:02

what you have, it may

17:04

well get eroded over time because other things are

17:06

going to eventually protect it. The

17:09

other pool is that companies are beginning

17:11

to not only mitigate the risks, but

17:13

also look at

17:15

alternative areas of growth. So, where is my

17:17

industry going in the future? Or

17:20

how can I position myself to

17:22

react to future opportunities and perhaps

17:25

lead my sector? What

17:27

are the real world impacts of this race to

17:29

rebalance? Yeah, I mean, I

17:32

think it is multi-dimensional. As

17:34

companies begin to think about

17:36

alternative supplier pools, these

17:38

new suppliers have the opportunity to get

17:40

into value chains that they were shut

17:43

out from before. If a certain company

17:45

was mainly sourcing from China and now

17:47

they're thinking that they're going to look

17:49

for 50% of their suppliers from Southeast

17:51

Asia, will these suppliers in Southeast Asia

17:53

now have a tremendous opportunity to get

17:55

into these more regionalized value chains? Now,

17:58

these value chains may be in Southeast Asia. these days,

18:00

it may be in the Middle East, Central East and

18:02

Europe, Latin America, it brings

18:04

more players into these

18:06

value chains. Now,

18:08

what this then does if you continue down the value

18:10

chain is you begin to create new ecosystems,

18:13

supplier hubs, manufacturing hubs, which in

18:16

itself brings in more talent. People

18:18

want to come in and

18:21

actually be schooled and learn skills in these

18:23

areas, as well as then also eventually get

18:25

jobs in these areas. So you start to

18:27

create new regions which get

18:29

known for particular sectors. So perhaps a

18:32

region in Malaysia is known for medical

18:34

devices, and another region in Indonesia is

18:36

known for developing auto parts. And you've

18:39

got a part in Central East and

18:41

Europe, which is known for electric

18:43

vehicle batteries and so on and so on. So

18:45

you start to get more

18:47

hubs that become known

18:49

for specific sectors and

18:52

specific parts of value chain.

18:54

That fragmentation creates opportunity. Darcy

18:57

also spoke about the critical

18:59

role of technology in managing

19:02

supply chains, including the impact

19:04

of Gen AI. Now, to

19:07

those organizations who are still in

19:09

the process of digitizing their supply

19:12

chains, David, what's your advice?

19:14

Well, I think it's becoming increasingly

19:17

clear that if you haven't started to

19:19

digitalize or increase the amount of technology

19:21

or how technology enables your value chain

19:23

is, you need to start pretty quickly.

19:26

And if you have started, you need

19:28

to accelerate it. However,

19:30

there's an element of practicality that

19:32

comes into that because most companies

19:35

can't completely digitize their complete operating

19:37

model all at once. And

19:39

therefore, there's an element of prioritization. So

19:42

where is the greatest need? Where

19:44

do I need to deploy the greatest resilience?

19:47

How do I mitigate the greatest threats? But

19:49

also, how can I position myself to be

19:52

the most competitive and address

19:54

future opportunities? And

19:56

understanding those elements really direct which

19:59

parts of your value chain. value

20:01

chain, you can prioritize indigitizing and

20:03

bringing greater technology and greater AI access

20:05

to that and actually prioritize where in

20:07

the value chain you're going to get

20:10

the best return based on the current

20:12

situation. Now, we've talked about

20:14

the challenges, but what are the future

20:16

areas of growth and opportunities for

20:18

businesses who get this right and de-risk

20:20

their supply chains? Yeah,

20:22

I mean, I think we're beginning to see some

20:25

of the benefits of those who began to

20:28

rebalance their value chains,

20:31

post-COVID and the

20:33

previous issues in SIRS Canal and

20:35

trade disputes. I mean, if

20:37

you just think about what's happening recently in the

20:39

Red Sea, you see certain companies being able to

20:41

pivot and still

20:44

serve their customers by alternative

20:46

means. And that's because the

20:48

measures they've taken have given

20:50

them greater agility to deal

20:52

with risks and disruptions that

20:54

have occurred. They've accepted the

20:56

fact that continuous disruption is

20:58

going to be a characteristic

21:01

of the future global economy, and

21:04

they've taken measures to address that.

21:06

So they've become more resilient, they've

21:08

retained the trust of their consumers

21:10

and customers and therefore developed a

21:13

sustainable business model. But also

21:16

what that agility gives

21:18

you is the ability to

21:20

respond to future opportunities, but also

21:23

to try new things

21:25

and perhaps bring new products and services

21:27

to market without having to disrupt your

21:29

whole value chains. Because

21:31

as the value chains have become more

21:33

regionalized compared to being one

21:35

global supply chain, you can try bringing new

21:38

product services in a different part of your

21:40

value chain, part of a different market without

21:42

actually having to commit the rest of your

21:44

business to that change. So you can begin

21:47

to see companies try to bring new products

21:49

and services to market, try to reinvent parts

21:51

of their business a lot quicker without it

21:53

being a risk to the whole of their

21:56

business. David, do you have

21:58

any examples of clients and providers? as

22:00

you work with. So you think are really

22:02

getting this right? If

22:04

we take an example, which is quite

22:06

topical in the sector of the electric

22:09

vehicle batteries. So

22:11

we're working with a company that's headquartered

22:13

out here in Southeast Asia as

22:16

they look to get closer to

22:18

the manufacturers in Western Europe. So

22:21

these manufacturers are asking them in this

22:23

company to get closer to them to

22:26

ensure that they shorten the

22:28

value chain so there's less risk in the value

22:30

chain. What then is happening

22:32

is that supplier, well, they're more than likely

22:35

asked their suppliers to follow them to come

22:37

closer. So you're seeing this in the

22:40

regionalization of supply chains across the world,

22:42

whether that might be companies who historically

22:44

might have manufactured most of their products

22:46

in Asia, beginning to regionalize and set

22:48

up a lot of their manufacturing in

22:51

Europe, or perhaps move to some of

22:53

their manufacturing to Central America to serve

22:55

the United States. It's beginning to break

22:57

up and become a lot more regionalized.

22:59

What is the role of governments and policymakers

23:01

in all of this? I think

23:04

what we can see is that the

23:06

role of government is to facilitate companies

23:09

becoming more agile. Now

23:11

within that, there's one particular area that I

23:13

think is key and that

23:15

is talent and you know, what role

23:17

can government play in

23:19

companies developing new talent

23:22

pools. So helping companies

23:24

create talent pools rather than

23:26

purely consume talent pools, particularly

23:28

as talent in particular

23:31

areas becomes highly sought after.

23:33

And so how can business work

23:35

with government and local education authorities

23:38

to help them develop new curriculums

23:40

and quickly skill young graduates to

23:42

come into the market and be

23:44

ready with the most relevant skills

23:46

for the future global economy. And

23:49

David, what are you

23:51

advising companies who are looking

23:53

to navigate these uncertain

23:55

times? What's your top advice to

23:57

people right now? I think... A

24:00

lot of our clients are coming to us from

24:02

a position of assessing

24:04

risk. They see threats

24:07

and disruptions throughout their value

24:09

chains coming from different directions across different

24:11

parts of the world. And

24:13

that is understandable. I think what we are trying

24:15

to help them with is first of all, how

24:17

do you sort of evaluate and manage

24:20

that risk? So going beyond risk and

24:22

looking at growth and opportunity. If you

24:24

purely look at risk and mitigate for

24:26

that, you're really only protecting what

24:28

you have today. Encouraging our

24:31

clients to think about where

24:33

their industry is going, where

24:35

future opportunities will be and

24:37

understanding how they might position

24:39

themselves to take advantage of

24:41

those and address those future

24:43

opportunities. It might not be

24:45

immediately, but at least if

24:47

they're positioned to take

24:49

advantage and address those future opportunities, that

24:52

enables them to be well-balanced.

24:56

Well, David, thank you so much

24:58

for your time and for joining us.

25:00

That was a really interesting conversation. Thanks

25:02

for your insight. Thank you very much. It's

25:04

been a pleasure to be with you today. I

25:08

have to say, I never thought I'd

25:10

be so riveted by conversation about supply

25:12

chains, but it has been absolutely fascinating

25:14

because it's something you probably don't think

25:17

about on a day-to-day level because you're

25:19

so used to things just arriving in

25:21

time and you're used to the product

25:23

being there when you need them.

25:25

But of course, supply chains are so important.

25:28

And I think this episode really

25:30

shone a light on they're not

25:32

just important to a business

25:35

and to the bottom line. They're really

25:38

important to wider society. And so

25:40

it's one of these issues where

25:42

it's actually really germane to so

25:44

many businesses. Well,

25:47

and that feels like something we've come

25:49

back to again and again over this

25:52

season, this kind

25:55

of feeling of inflection point, whether

25:57

we are talking about people. and

25:59

how they need to be upskilled,

26:02

or whether we are talking about

26:04

generative AI, and how to

26:06

use it in a responsible manner, or whether we

26:08

are talking, as we have done several times on

26:11

this season, about climate change,

26:13

and where and how different

26:15

companies can think about this moment and

26:18

prepare for a future. And I think

26:20

what you've just touched on there is

26:22

really interesting, because I think there are

26:24

issues which people can be quite frightened

26:26

of, but actually you can't afford not

26:29

to get on top

26:31

of these big issues. Everybody

26:33

needs to educate themselves about these

26:35

big currents that are happening in

26:38

business and in society and in

26:40

economics and the wider world. And

26:42

it's having an open mind about

26:44

this stuff is almost as important

26:47

as then getting the right systems

26:49

in place. Well,

26:52

that brings us to the end of

26:54

this episode and this second series of

26:56

Take On Tomorrow. A big

26:59

thank you to all who joined us.

27:01

We've had so many fascinating conversations, on

27:04

topics ranging from building sustainable

27:06

cities to generative AI to

27:09

recording live at COP28 and Davos. And

27:13

if you've missed any of the episodes,

27:15

tap follow or subscribe in your podcast

27:17

app to get them all. And

27:19

if you've enjoyed this season, please leave

27:21

us a review. It will help others

27:23

find Take On Tomorrow. Take

27:25

On Tomorrow is brought to you

27:27

by PwC's strategy and business. PwC

27:30

refers to the PwC network

27:32

and or one or more of its

27:34

member firms, each of which is a

27:36

separate legal entity.

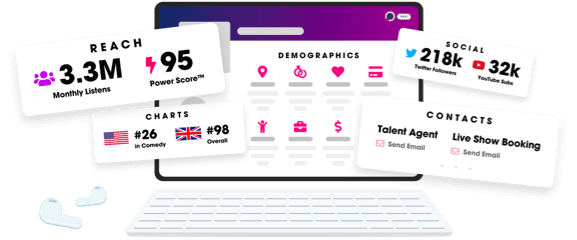

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2025 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us